3D tools are revolutionizing how car engines are designed, prototyped, and manufactured. From concept to creation, these powerful tools offer unprecedented control and precision, enabling engineers to push the boundaries of performance and efficiency.

Designing the Future of Automotive: 3D Tools in Engine Creation

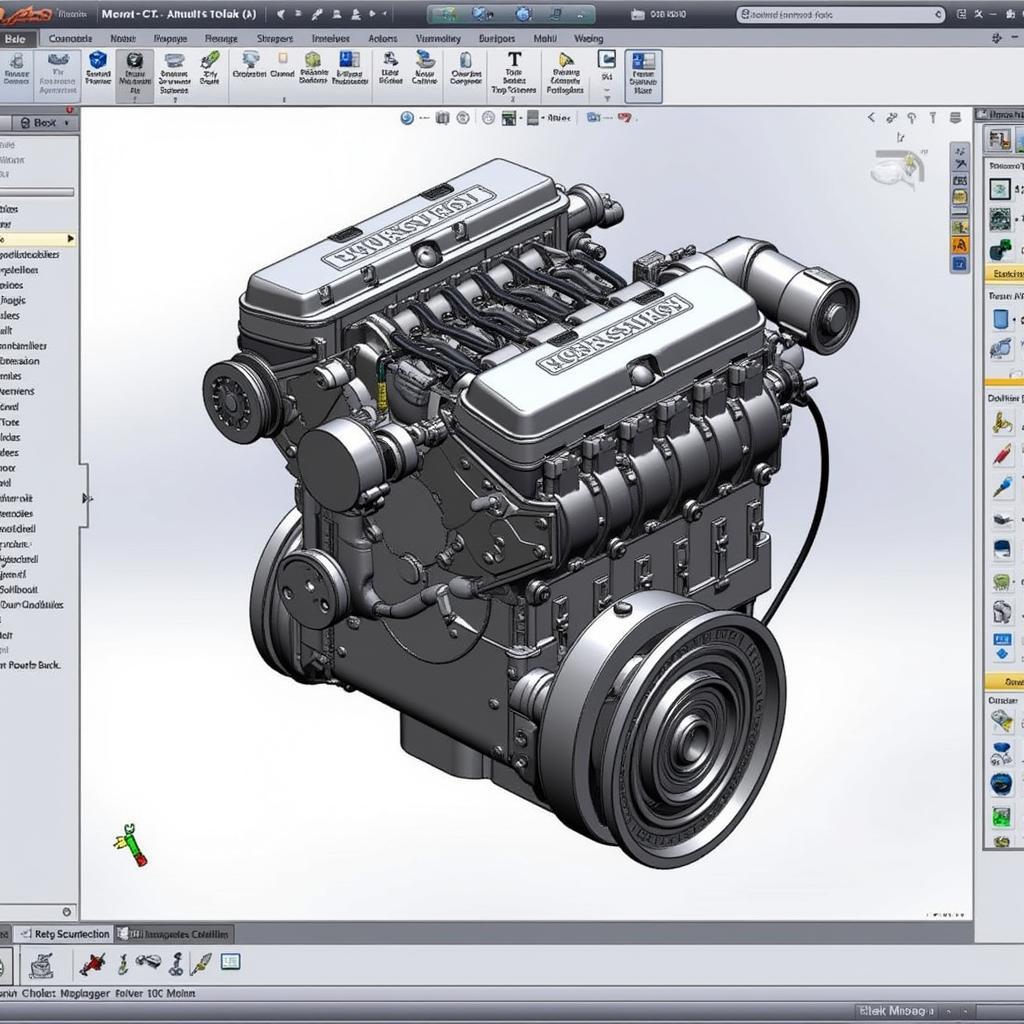

3D modeling software lies at the heart of modern engine development. Programs like Autodesk Inventor, SolidWorks, and Siemens NX allow engineers to create incredibly detailed digital representations of engine components. These virtual engines can be rotated, zoomed, and dissected to examine every detail. This allows for early identification and correction of design flaws, saving significant time and cost compared to traditional prototyping methods. What’s more, these tools facilitate collaborative design, enabling teams across the globe to work on the same project simultaneously.

From Digital Design to Physical Reality: 3D Printing and Engine Prototyping

3D printing, also known as additive manufacturing, is transforming the prototyping phase of engine development. tools used in car manufacturing are evolving with this technology. By using 3D printers, engineers can quickly and affordably create physical prototypes of engine components directly from their digital designs. This allows for rapid iteration and testing of different design concepts, accelerating the overall development process. Furthermore, 3D printing enables the creation of complex geometries that would be difficult or impossible to manufacture using traditional methods.

How 3D Printing is Changing Engine Manufacturing

3D printing is not just for prototypes. It’s also increasingly used for the production of specialized engine components, particularly in high-performance and motorsport applications. laser alignment tool for race cars can be used in conjunction with 3D printed parts to ensure optimal performance. The ability to create highly customized parts on demand is a game-changer for the automotive industry.

“3D printing allows us to explore design options that were previously unimaginable,” says Dr. Amelia Carter, a leading automotive engineer. “The speed and flexibility of this technology are truly transformative.”

Simulation and Analysis: Optimizing Engine Performance with 3D Tools

Sophisticated 3D simulation software plays a crucial role in optimizing engine performance. Computational Fluid Dynamics (CFD) software allows engineers to simulate the flow of air, fuel, and exhaust gases through the engine. This helps them identify potential bottlenecks, optimize combustion efficiency, and improve overall engine performance. Finite Element Analysis (FEA) software, on the other hand, is used to simulate the structural integrity of engine components under various stress conditions, ensuring durability and reliability. You can use portable car alignment tools to further enhance engine performance.

“Simulation software is essential for pushing the limits of engine performance,” explains Professor David Miller, an expert in automotive engineering. “It allows us to test and refine designs in a virtual environment before building physical prototypes, saving valuable time and resources.” Modern car frame measurement tool can be integrated with this data to ensure accurate manufacturing. What tools are needed to assemble a car, you ask? Check out tools to make a car to learn more.

Conclusion

3D tools are fundamentally changing the way car engines are designed, prototyped, and manufactured. From the initial design stages to final production, these tools offer unparalleled precision, efficiency, and flexibility. As the technology continues to evolve, we can expect even more innovative applications of 3D tools in the automotive industry.

FAQ

- What are the most common 3D modeling software used in automotive engineering?

- How does 3D printing reduce the cost of engine prototyping?

- What are the advantages of using CFD simulation in engine design?

- Can 3D printing be used to produce entire car engines?

- What are the limitations of using 3D tools in engine manufacturing?

- How do these tools improve engine efficiency?

- What are some future applications of 3D technology in the automotive industry?

Need assistance? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 910 Cedar Lane, Chicago, IL 60605, USA. Our customer service team is available 24/7.