The Eastwood on car flairing tool for 3/16 tubing is a crucial tool for anyone working with brake lines, fuel lines, or other automotive tubing. This specialized tool helps create precise flares, ensuring leak-free connections and optimal system performance. Whether you’re a professional mechanic or a DIY enthusiast, understanding how to use this tool effectively is essential for achieving professional-grade results.

Understanding the Importance of Flairing 3/16 Tubing

Proper flaring is paramount when working with 3/16 tubing in automotive applications. A well-executed flare creates a secure seal, preventing leaks and maintaining the integrity of the system. Without a proper flare, you risk fluid leaks, system failure, and even potential safety hazards. The Eastwood on car flairing tool offers a reliable solution for creating these critical flares efficiently and accurately. Using the correct tool, like the Eastwood, for your 3/16 tubing ensures compatibility and minimizes the risk of damage. It’s an investment in the longevity and safety of your vehicle’s systems.

Investing in a quality flaring tool like the Eastwood on car flaring tool is a smart move. It saves you time and frustration in the long run by producing consistent, leak-proof flares every time.

Choosing the Right Eastwood On Car Flairing Tool

Eastwood offers a range of flaring tools. Selecting the right one depends on your specific needs and the type of flare required. Double flares are common in automotive applications, providing extra strength and a more secure seal. The Eastwood on car flairing tool is specifically designed to create these double flares with ease. Consider the materials you’ll be working with and choose a tool that’s compatible with 3/16 tubing.

When choosing a flaring tool, also consider the material of the tool itself. A durable, high-quality tool will last longer and provide more consistent results.

How to Use the Eastwood On Car Flairing Tool for 3/16 Tubing

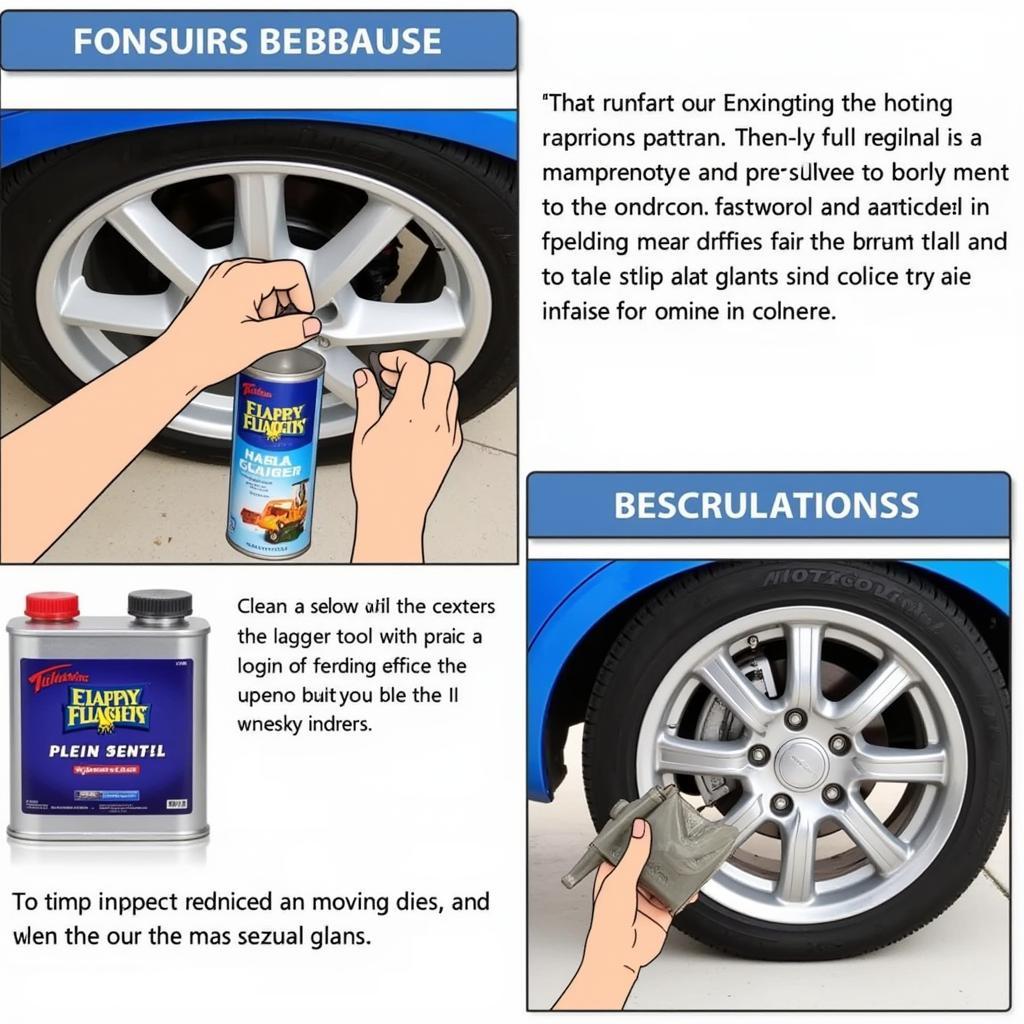

Using the Eastwood on car flairing tool is a straightforward process. First, cut the 3/16 tubing to the desired length using a tubing cutter. Ensure the cut is clean and square. Next, place the tubing into the appropriate die on the flaring tool. The die should match the outer diameter of the tubing. Then, tighten the clamp securely to hold the tubing in place. Finally, using the flaring cone, slowly and evenly apply pressure to create the double flare.

Remember to lubricate the tubing and the flaring cone before each use to ensure smooth operation and prevent damage to the tool and the tubing.

Common Mistakes to Avoid When Flairing Tubing

Several common mistakes can lead to imperfect flares and potential leaks. Over-tightening the flaring cone can crush the tubing. Applying uneven pressure can result in an asymmetrical flare. Using the wrong size die can damage the tubing or create a weak flare. Avoiding these mistakes will ensure a perfect, leak-proof flare every time.

Another common mistake is neglecting to properly deburr the tubing after cutting. Burrs can interfere with the flaring process and create a weak point in the flare.

“Always remember to double-check the compatibility of your tooling with the specific 3/16 tubing you are using. Different materials may require different flaring techniques,” advises John Smith, Senior Automotive Technician at DiagFixPro.

Maintaining Your Eastwood On Car Flairing Tool

Proper maintenance is essential for ensuring the longevity of your Eastwood on car flairing tool. Keep the tool clean and lubricated. Store it in a dry place to prevent rust and corrosion. Regularly inspect the dies and the flaring cone for any signs of wear or damage. Replacing worn parts will ensure the tool continues to perform optimally.

“Regularly cleaning and lubricating your flaring tool will not only extend its life but also improve the quality of your flares,” adds Sarah Jones, Lead Mechanic at DiagFixPro.

Maintaining Your Eastwood On Car Flairing Tool

Maintaining Your Eastwood On Car Flairing Tool

Conclusion

The Eastwood on car flairing tool for 3/16 tubing is a valuable asset for anyone working on automotive tubing systems. By understanding the importance of proper flaring techniques and following the correct procedures, you can achieve professional-grade results and ensure the reliability and safety of your vehicle’s systems. Invest in a quality Eastwood on car flairing tool and master the art of creating perfect flares.

FAQ

- What type of flare is recommended for automotive brake lines? Double flares are typically recommended for automotive brake lines.

- How often should I lubricate my flaring tool? Lubricate the tool before each use for optimal performance.

- What size tubing is the Eastwood on car flairing tool designed for? This specific tool is designed for 3/16 tubing.

- Can I use this tool for other types of metal tubing? Check the manufacturer’s specifications for compatibility with other metal types.

- What should I do if my flares are leaking? Inspect the flare for any imperfections and ensure the correct flaring technique was used.

- Where can I buy replacement parts for my Eastwood flaring tool? Replacement parts can be purchased from Eastwood or authorized retailers.

- What is the advantage of using a double flare? Double flares provide a stronger, more secure seal compared to single flares.

Common Scenarios and Questions

- Scenario: Leaking brake lines after flaring. Possible Cause: Improper flaring technique, incorrect die size, or damaged tubing.

- Question: Can I use this tool with stainless steel tubing? Consult the manufacturer’s guidelines for compatibility.

Related Resources

For further information on car diagnostic tools and techniques, explore other articles on DiagFixPro.

Need Help? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 910 Cedar Lane, Chicago, IL 60605, USA. Our 24/7 customer support team is ready to assist you.

Leave a Reply