Car Manufacturing Tooling is the backbone of the automotive industry. From the initial design stages to the final assembly, these specialized tools shape, mold, and assemble the various components that make up a vehicle. Understanding the complexities of car manufacturing tooling is essential for anyone involved in the automotive sector, from engineers to business owners.

Car Manufacturing Tooling – Press

Car Manufacturing Tooling – Press

One crucial aspect of car manufacturing tooling is the materials used. High-strength steel, aluminum alloys, and composite materials are frequently employed due to their durability and ability to withstand the demanding manufacturing process. The specific tooling required depends heavily on the material being worked with. For instance, stamping tools for high-strength steel require different properties than those used for aluminum. This also relates to careers paths such as tool and die making, best career change from tool and die explores some options.

Types of Car Manufacturing Tooling

Different stages of car production necessitate various types of tooling. Here are a few key examples:

Stamping Dies

These tools are used to cut and shape sheet metal into body panels, doors, and other structural components. They are crucial for high-volume production and require precision engineering to ensure consistent and accurate results. car parts stamping tools discusses this further.

Casting Molds

These molds are designed to create complex shapes by pouring molten metal into a pre-formed cavity. Engine blocks, transmission casings, and other intricate parts are often manufactured using casting molds.

Welding Fixtures

These tools hold components in place during the welding process, ensuring precise alignment and consistent weld quality. They are essential for maintaining structural integrity and safety in the finished vehicle.

Assembly Jigs

These tools guide and position parts during the assembly process, ensuring proper fit and function. They are especially important for complex assemblies like dashboards and powertrain systems. china car tools offers a look at the tools coming from this manufacturing giant.

Robotic Welding Fixture in Automotive Assembly

Robotic Welding Fixture in Automotive Assembly

“The quality of the tooling directly impacts the quality of the final product,” says John Miller, a Senior Manufacturing Engineer with 20 years of experience. “Investing in high-quality car manufacturing tooling is an investment in the long-term success of any automotive manufacturer.”

The Importance of Precision and Maintenance

Car manufacturing tooling demands extreme precision. Even minor discrepancies can lead to significant issues in the final product. Regular maintenance and calibration are essential to ensure that tools continue to perform at their optimal level. This is also true for other precision manufacturing, such as china health care device parts tooling.

What are the future trends in car manufacturing tooling?

The future of car manufacturing tooling is being shaped by advancements in automation, materials science, and digital technologies. Robotics, 3D printing, and artificial intelligence are playing increasingly important roles in the design, production, and maintenance of these tools.

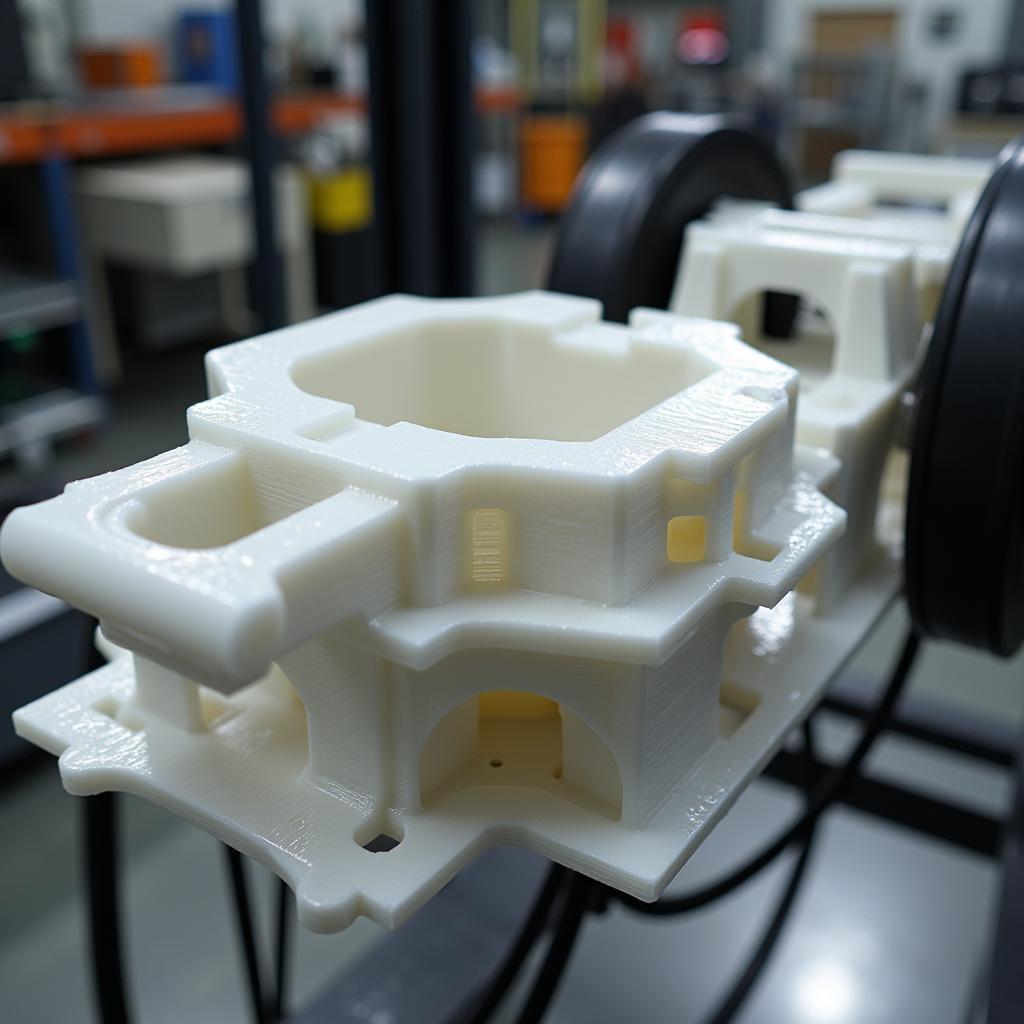

3D Printed Car Manufacturing Tool

3D Printed Car Manufacturing Tool

What are the challenges facing car manufacturers regarding tooling?

One of the major challenges is the high cost of tooling, especially for low-volume production runs. Finding the right balance between cost and quality is a constant struggle for manufacturers.

“Staying ahead of the curve in terms of technology is critical,” adds Dr. Sarah Chen, a leading researcher in materials science. “New materials and manufacturing processes require innovative tooling solutions.” Thinking about a career in tooling? is tools engineer a good career path offers some insight.

Conclusion

Car manufacturing tooling plays a vital role in the production of modern vehicles. Understanding the different types of tooling, the importance of precision and maintenance, and the future trends in this field is critical for success in the automotive industry. Investing in high-quality car manufacturing tooling is crucial for ensuring the production of safe, reliable, and high-performing vehicles.

FAQ

- What are the main types of car manufacturing tooling?

- Why is precision so important in car manufacturing tooling?

- How does tooling affect the cost of car production?

- What are the emerging trends in car manufacturing tooling?

- How can car manufacturers optimize their tooling investments?

- What is the role of 3D printing in car manufacturing tooling?

- How can preventative maintenance extend the lifespan of tooling?

For further support, please contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 910 Cedar Lane, Chicago, IL 60605, USA. Our customer service team is available 24/7.

Leave a Reply