Building an old car engine is a rewarding experience that blends mechanical skill with a touch of artistry. Whether you’re restoring a classic muscle car or giving new life to a vintage ride, having the right tools and knowledge is essential. This guide provides a comprehensive overview of the essential tools and techniques for building an old car engine, equipping you with the knowledge to tackle this exciting project.

Gathering Your Arsenal: Must-Have Tools for Engine Building

Before you even think about cracking open that engine block, you’ll need to assemble a proper set of tools. A comprehensive automotive tool kit for car is a great starting point, but building an old car engine often requires specialized equipment. Essential tools include a quality torque wrench, ring compressors for pistons, a valve spring compressor, and a variety of specialized sockets and wrenches. Don’t skimp on quality – investing in durable, reliable tools will save you headaches in the long run.

Precision Measuring Tools: The Key to a Smooth-Running Engine

Accurate measurements are the cornerstone of a successful engine rebuild. Micrometers, dial indicators, and bore gauges are crucial for checking tolerances and ensuring that all components fit together perfectly. These tools allow you to measure critical dimensions like crankshaft journals, cylinder bores, and piston ring gaps, guaranteeing proper clearances and preventing premature wear.

Disassembly and Inspection: Laying the Foundation

Once your tools are assembled, the next step is carefully disassembling the engine. Meticulously label and organize all parts as you remove them – this will be invaluable during the reassembly process. After disassembly, thoroughly clean all components. This not only reveals any hidden damage but also ensures a clean working environment.

Identifying Wear and Tear: A Critical Assessment

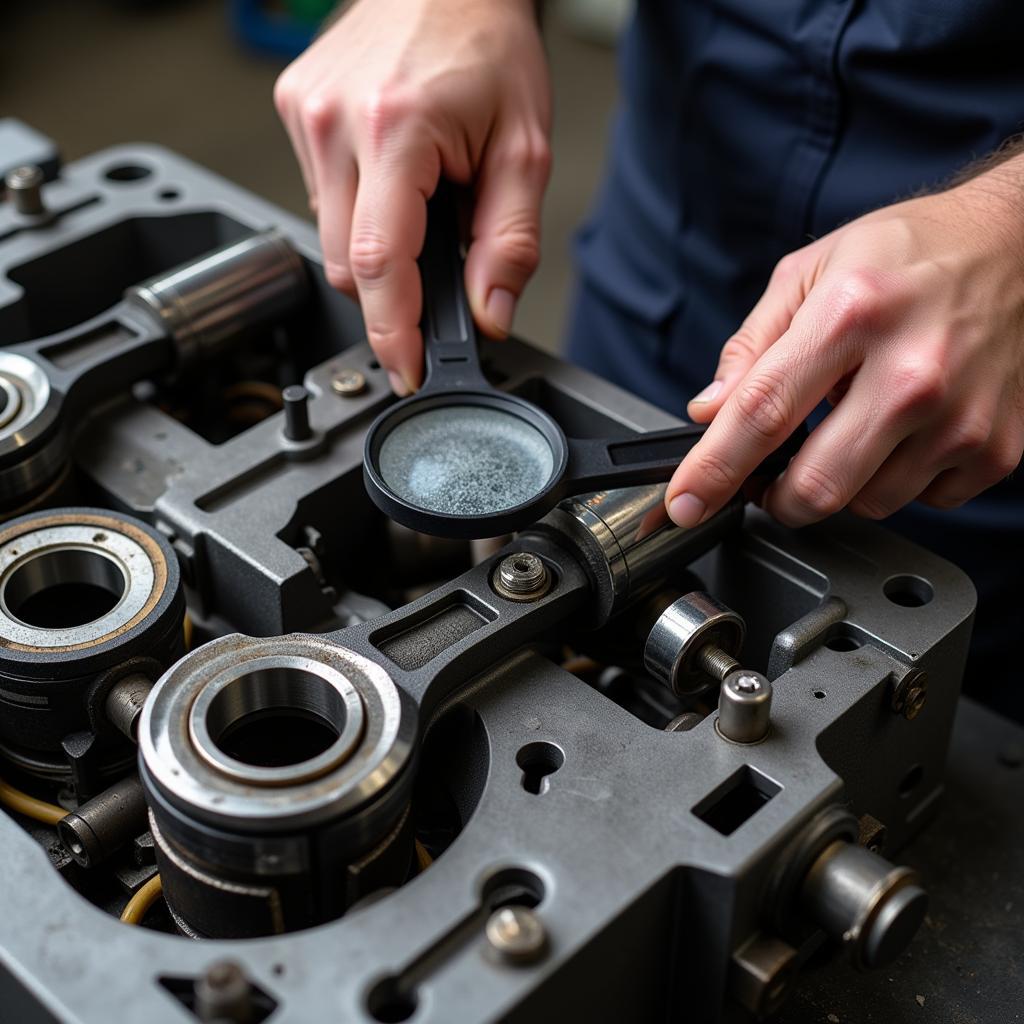

Engine Component Inspection – A close-up view of a mechanic inspecting engine components for wear and tear.

Engine Component Inspection – A close-up view of a mechanic inspecting engine components for wear and tear.

Inspect every component for signs of wear, damage, or excessive clearances. Pay particular attention to the crankshaft bearings, connecting rods, and pistons. Any worn or damaged parts should be replaced or machined back to specifications.

Reassembly: Building a Powerful Heart

With the engine components cleaned and inspected, the reassembly process begins. This is where precision and attention to detail are paramount. Lubricate all moving parts with assembly lube to prevent initial startup wear. Torque all fasteners to the manufacturer’s specifications using a torque wrench. This ensures proper clamping force and prevents leaks.

Honing Your Skills: Essential Techniques for Engine Building

Building an old car engine isn’t just about bolting parts together. It involves honing your skills in areas like gapping piston rings, setting valve clearances, and installing bearings correctly. These seemingly small details have a significant impact on the engine’s performance and longevity.

“Properly gapping piston rings is critical for oil control and preventing blow-by,” says veteran engine builder, John Miller. “A small gap can lead to ring seizure, while a large gap results in excessive oil consumption.”

Testing and Tuning: The Final Touches

After reassembly, the engine should be tested and tuned. This may involve running the engine on a test stand or installing it in the vehicle and performing a break-in procedure. Proper tuning ensures optimal performance, fuel efficiency, and engine longevity.

“A well-tuned engine not only delivers impressive power but also runs smoothly and efficiently,” adds Miller. “It’s the culmination of all your hard work and attention to detail.”

Conclusion: Revitalizing Automotive History

Building an old car engine is a challenging yet incredibly satisfying endeavor. With the right tools, knowledge, and a healthy dose of patience, you can breathe new life into a classic engine and enjoy the thrill of hearing it roar back to life. Remember to meticulously follow the manufacturer’s specifications and invest in quality tools. Your dedication will be rewarded with a powerful and reliable engine that stands the test of time. When choosing the right tools for your next classic car project, check out our guide on classic car travel tool kit. Need a specialized tool? Look into our review of the sears tool kit for car. If you’re interested in tool design planning career, building an engine can be an excellent starting point. Looking for more general automotive tools? Check our recommended assetto corsa car mod tool.

FAQ

-

What is the most important tool for building an old car engine? A torque wrench is arguably the most crucial tool, ensuring proper fastener tightening.

-

How do I determine the correct clearances for engine components? Consult the engine’s service manual for specific clearance specifications.

-

What type of oil should I use during the break-in period? Use a break-in oil specifically designed for new or rebuilt engines.

-

How long should the break-in period last? Break-in procedures vary, but typically involve a few hundred miles of driving under specific conditions.

-

What are some common mistakes to avoid during engine building? Common errors include improper torque specifications, incorrect ring gap, and forgetting to lubricate components.

Need assistance with your car diagnostic project? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 910 Cedar Lane, Chicago, IL 60605, USA. Our 24/7 customer support team is ready to help.

Leave a Reply