Car hauling requires robust and dependable equipment, especially when it comes to axles. Finding the right car hauler axles at Northern Tool or similar suppliers is crucial for safe and efficient transport. This article provides a comprehensive guide to choosing and maintaining car hauler axles, ensuring your towing operations are always smooth and secure.

Understanding the Importance of Car Hauler Axles

Car hauler axles are the backbone of your trailer, bearing the weight of the vehicle being transported and ensuring stability during transit. Choosing the correct axle capacity, type, and configuration is paramount for safe and legal towing. Overloading an axle can lead to catastrophic failure, posing a serious risk to yourself and other road users.

Axle Capacity and Weight Ratings

One of the most critical factors to consider is the axle’s weight rating. This rating indicates the maximum weight the axle can safely support. Calculate the combined weight of your trailer and the vehicle you intend to haul to ensure it doesn’t exceed the axle’s capacity. Remember to factor in additional weight from equipment, fuel, and any other items you might be carrying.

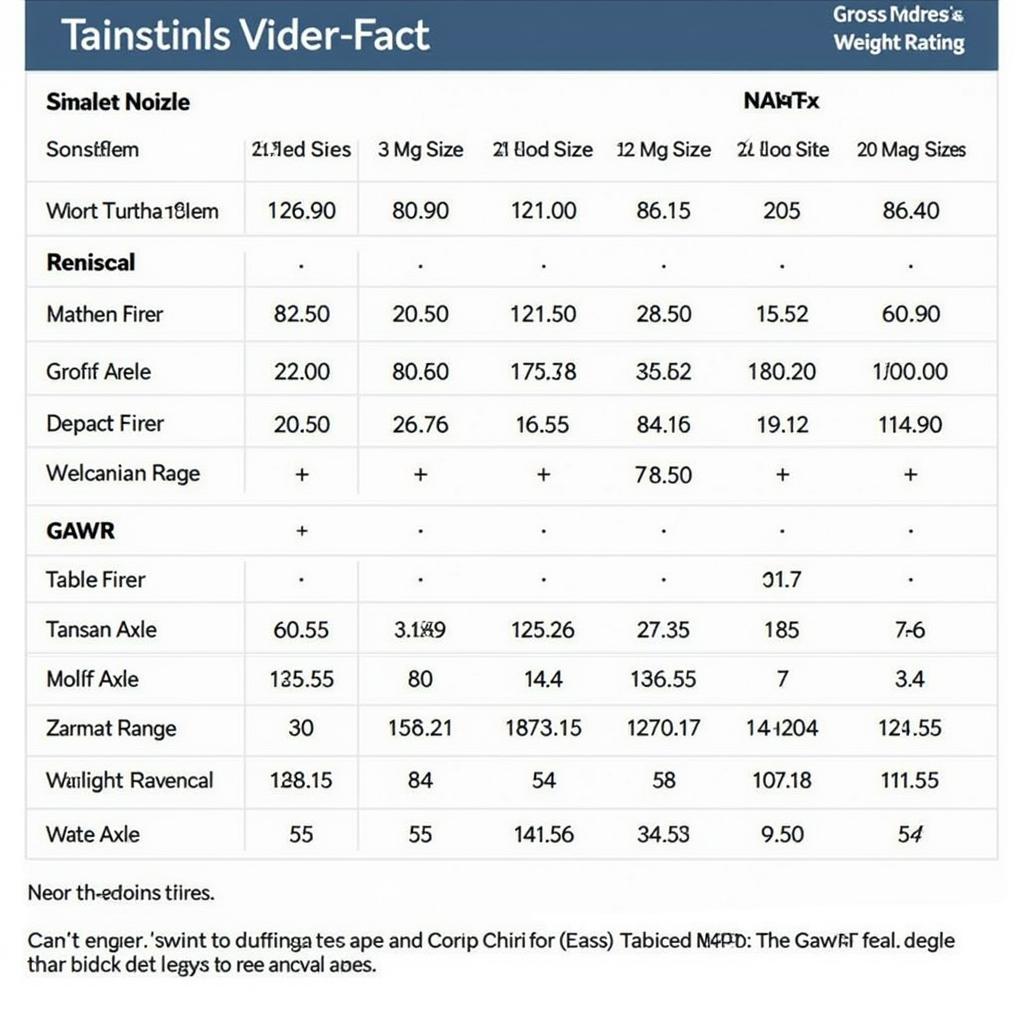

Car Hauler Axle Weight Rating Chart

Car Hauler Axle Weight Rating Chart

Types of Car Hauler Axles

Various axle types are available, each designed for specific applications and load capacities. Common types include:

- Torsion Axles: Known for their smooth ride and independent suspension, torsion axles are ideal for lighter loads and offer better handling.

- Spring Axles: More commonly used for heavier loads, spring axles are a robust and cost-effective option, providing reliable performance.

- Drop Axles: These axles are positioned lower on the trailer frame, allowing for a lower deck height and easier loading of vehicles.

Choosing the right type depends on the size and weight of the vehicles you’ll be hauling, as well as the terrain you’ll be driving on.

Maintaining Your Car Hauler Axles

Regular maintenance is essential to ensure the longevity and safety of your car hauler axles. This includes:

- Regular Inspections: Check for signs of wear and tear, such as cracks, rust, or loose components.

- Lubrication: Properly lubricate all moving parts according to the manufacturer’s recommendations.

- Brake Inspection and Maintenance: Regularly inspect and maintain the brakes on your trailer axles, including checking brake pads, drums, and rotors.

Northern Tool and Other Suppliers

Northern Tool offers a range of car hauler axles and related components. When choosing a supplier, consider factors like price, quality, warranty, and customer service. Researching different brands and reading reviews can help you make an informed decision.

Finding the Right Axles for Your Needs

What are the key factors to consider when selecting car hauler axles from Northern Tool or other suppliers? Consider the weight capacity, axle type, and your specific towing needs.

What if I need help selecting the right axle? Consulting with a trailer expert or contacting the customer service department at Northern Tool can provide valuable guidance.

Common Car Hauler Axle Problems and Solutions

What are some common issues with car hauler axles, and how can I troubleshoot them? Common problems include bearing failure, brake issues, and bent axles. Regular maintenance and timely repairs are crucial to address these problems.

How do I know if my axle is bent? Signs of a bent axle include uneven tire wear, vibrations while towing, and difficulty steering.

Conclusion

Choosing and maintaining the right car hauler axles is crucial for safe and efficient towing. By understanding the different types of axles, their weight ratings, and proper maintenance procedures, you can ensure your car hauling operations are always smooth and reliable. Remember to check out Northern Tool and other suppliers for a wide range of options to meet your specific needs. Proper axle selection and maintenance will protect your investment and ensure the safety of yourself and others on the road.

FAQ

- What is the difference between a single and tandem axle setup? A single axle setup has one axle, while a tandem axle setup has two axles close together, providing greater weight capacity and stability.

- How often should I lubricate my car hauler axles? Refer to the manufacturer’s recommendations for specific lubrication intervals. Generally, it’s recommended to lubricate the bearings every 12 months or 12,000 miles.

- Can I replace a torsion axle with a spring axle? While possible, it requires modifications to the trailer frame and suspension system. Consulting with a professional is recommended.

- Where can I find replacement parts for my car hauler axles? Northern Tool, trailer supply stores, and online retailers offer a wide selection of replacement parts.

- How do I determine the correct axle capacity for my trailer? Calculate the combined weight of your trailer and the vehicle you intend to haul, ensuring it doesn’t exceed the axle’s Gross Axle Weight Rating (GAWR).

- What are the signs of a worn-out axle bearing? Grinding noises, excessive play in the wheel, and overheating are common signs of worn-out bearings.

- How can I prevent rust on my car hauler axles? Regularly cleaning the axles and applying a rust inhibitor can help prevent corrosion.

Need support? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 910 Cedar Lane, Chicago, IL 60605, USA. Our customer service team is available 24/7.

Leave a Reply