Tooling in car manufacturing refers to the specialized tools, dies, jigs, fixtures, and other equipment used to create and assemble vehicle components. These tools play a crucial role in ensuring precision, consistency, and efficiency throughout the production process. From shaping metal body panels to molding plastic interiors, the right tooling is essential for producing high-quality vehicles. Choosing the correct tooling can drastically affect the final product and the overall manufacturing process.

The Importance of Tooling in the Automotive Industry

Tooling is the backbone of modern car manufacturing. It dictates the shape, size, and quality of every component, influencing everything from the aerodynamics of the car body to the fit and finish of interior parts. Investing in high-quality tooling is a significant upfront cost, but it translates to long-term benefits through reduced production time, minimal errors, and improved product quality. car manufacturing tooling is a complex and ever-evolving field.

Types of Tooling Used in Car Manufacturing

There are various types of tooling employed in car manufacturing, each designed for a specific purpose:

- Casting Dies: Used to create complex shapes by pouring molten metal into molds.

- Stamping Dies: Used to form sheet metal into body panels, doors, and other structural components.

- Injection Molds: Used to produce plastic parts like dashboards, bumpers, and interior trim.

- Welding Fixtures: Hold parts in place for precise and consistent welding.

- Assembly Jigs: Guide the assembly of multiple components, ensuring proper alignment and fit.

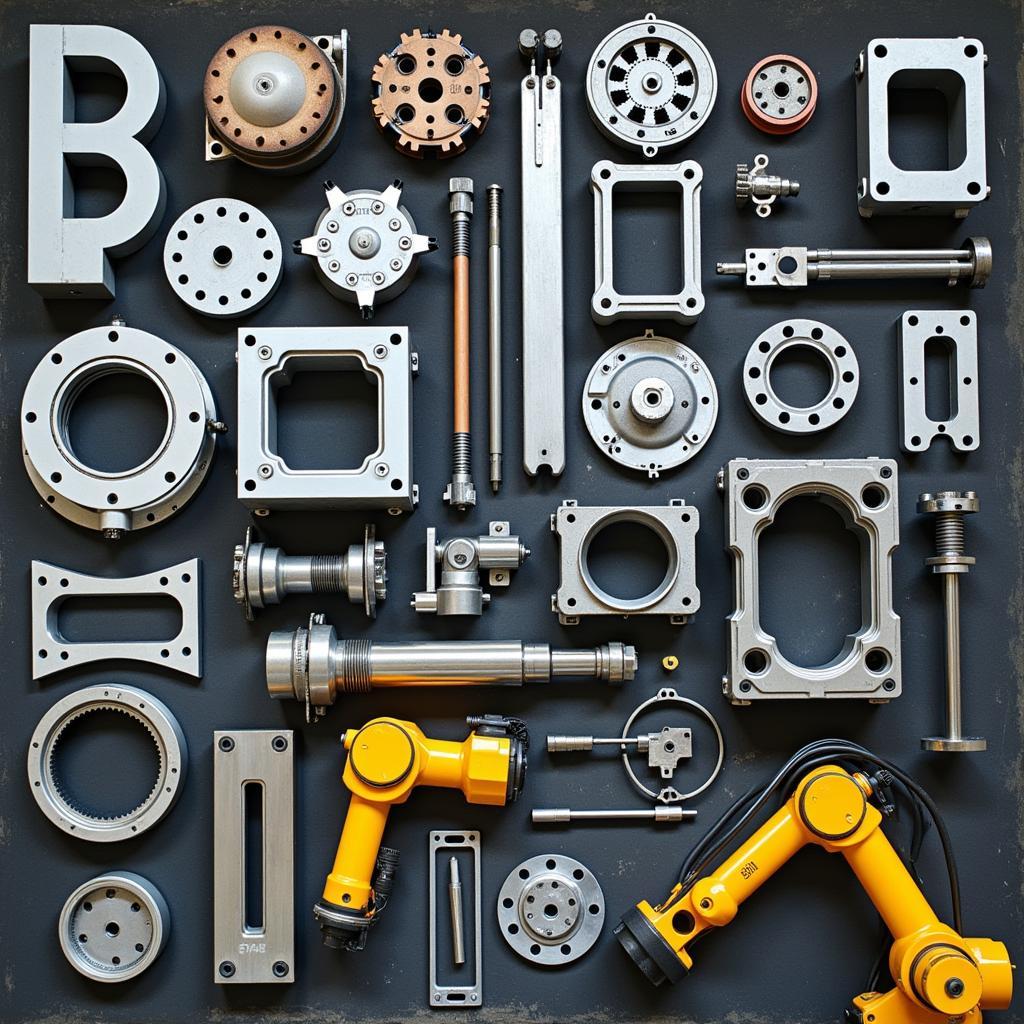

Examples of Car Manufacturing Tooling

Examples of Car Manufacturing Tooling

How Tooling Impacts Car Design and Production

Tooling heavily influences the design and production processes in the automotive industry. Early in the design phase, engineers consider tooling requirements to ensure that the proposed design can be manufactured efficiently and cost-effectively. The selection of tooling materials, the design of the tooling itself, and the manufacturing processes used to create the tooling all impact the final product’s quality and cost.

What are the benefits of advanced tooling?

Advanced tooling technologies, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), have revolutionized the tooling industry. These technologies allow for greater precision, faster production times, and more complex designs. tooling list for manufacturing car brakes for example, can be highly specialized.

- Improved Accuracy: CAD/CAM allows for the creation of highly accurate tooling, minimizing errors and ensuring consistent part quality.

- Reduced Lead Times: Automated tooling design and manufacturing processes significantly reduce the time it takes to bring new vehicles to market.

- Cost Savings: While the initial investment in advanced tooling can be high, it often leads to long-term cost savings through improved efficiency and reduced waste.

The Future of Tooling in Car Manufacturing

The automotive industry is constantly evolving, and tooling technology is keeping pace. With the rise of electric vehicles, lightweight materials, and additive manufacturing, the demand for innovative tooling solutions is higher than ever. Understanding what roles these new technologies play can lead to a promising career. Perhaps you should consider is machine tool technology a good career.

What role does tooling play in the production of electric vehicles?

The shift towards electric vehicles has created new challenges and opportunities for the tooling industry. The need for lightweight materials and complex battery systems requires specialized tooling solutions. For instance, car brake pad manufacturing process tooling list will continue to evolve alongside other car parts.

“The development of new tooling technologies is essential for the successful transition to electric vehicles,” says Dr. Emily Carter, a leading expert in automotive manufacturing. “We need tools that can handle new materials and manufacturing processes, while maintaining the highest standards of quality and efficiency.”

Conclusion

Tooling is an integral part of car manufacturing, influencing every stage of the process from design to assembly. Investing in high-quality and advanced tooling is crucial for producing high-quality, safe, and efficient vehicles. As the automotive industry continues to evolve, so too will the tooling technologies that support it, paving the way for more innovative and efficient car manufacturing processes. Understanding the role of tooling is essential for anyone involved in the automotive industry.

FAQ

- What is the most common type of tooling used in car manufacturing?

- How has tooling evolved with advancements in technology?

- What is the role of 3D printing in car manufacturing tooling?

- What are the key considerations when choosing tooling materials?

- How does tooling impact the cost of car manufacturing?

- What are the future trends in car manufacturing tooling?

- How does tooling contribute to the safety of vehicles?

Need help with car diagnostics or have questions about tooling? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 910 Cedar Lane, Chicago, IL 60605, USA. We have a 24/7 customer support team ready to assist you. You can also check out our other articles on china health care device parts tooling.

Leave a Reply