A beam profile gauge tool is essential for precise car modeling, ensuring accurate measurements and a flawless finish. Whether you’re a professional or a hobbyist, understanding how to use this tool effectively can significantly elevate your car modeling projects.

Understanding the Beam Profile Gauge Tool

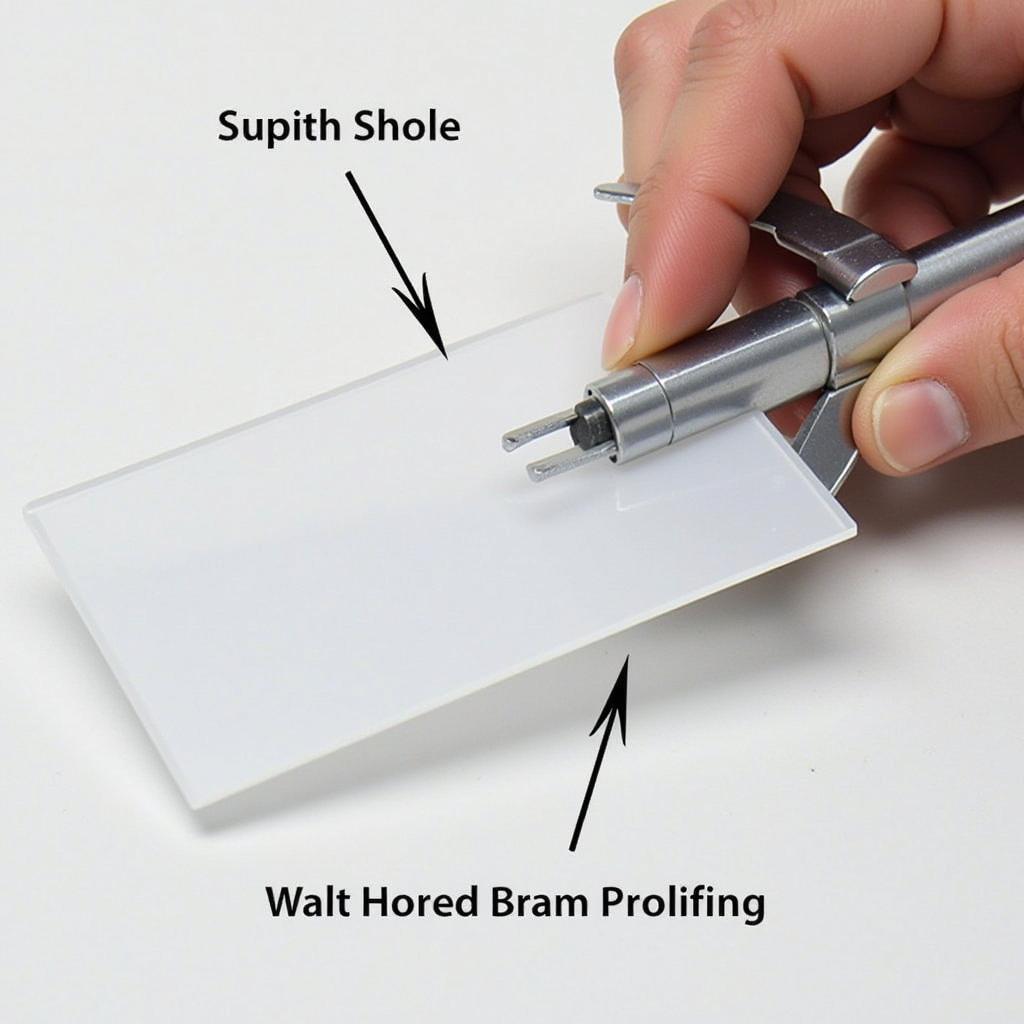

The beam profile gauge tool, also known as a caliper or thickness gauge, is a precision instrument used to measure the thickness of materials. In car modeling, it’s crucial for measuring the thickness of plastic sheets, metal plates, and other components. Accurate measurements are vital for ensuring proper fit and alignment during assembly.

Why is a Beam Profile Gauge Tool Important for Car Modeling?

Accuracy is paramount in car modeling. A slight deviation in measurement can lead to noticeable imperfections in the final product. The beam profile gauge tool helps maintain consistency and precision, resulting in a more professional-looking model. Furthermore, it allows modelers to replicate real-world car designs with greater fidelity.

Choosing the Right Beam Profile Gauge Tool

Selecting the appropriate beam profile gauge tool depends on the specific needs of your car modeling project. Consider the following factors:

- Material: Different materials require different measuring ranges. Ensure the gauge can accurately measure the thickness of the materials you commonly use.

- Precision: The level of precision required depends on the scale and complexity of the model. More detailed models demand higher precision measurements.

- Type: Various types of beam profile gauge tools are available, including digital, dial, and vernier calipers. Choose the type that best suits your preferences and skill level.

How to Use a Beam Profile Gauge Tool for Car Modeling

Using a beam profile gauge tool effectively is crucial for achieving accurate measurements. Here’s a step-by-step guide:

- Zero the Gauge: Before each use, calibrate the gauge to ensure accurate readings. This typically involves closing the jaws and adjusting the zero setting.

- Position the Material: Place the material to be measured between the jaws of the gauge. Ensure the material is flat and perpendicular to the jaws.

- Close the Jaws: Gently close the jaws until they make contact with the material. Avoid applying excessive pressure, which can distort the measurement.

- Read the Measurement: Read the measurement displayed on the gauge. For digital gauges, the measurement is displayed on the screen. For dial and vernier calipers, read the measurement from the scale.

Using a Beam Profile Gauge Tool in Car Modeling

Using a Beam Profile Gauge Tool in Car Modeling

Tips for Accurate Measurements

- Ensure the material is clean and free of debris.

- Take multiple measurements at different points to ensure consistency.

- Use a stable surface to support the material and the gauge.

- Avoid dropping or mishandling the gauge, which can damage the delicate mechanism.

Advanced Techniques with Beam Profile Gauge Tools

Beyond basic measurements, beam profile gauge tools can be used for more advanced car modeling techniques:

- Measuring Gaps and Clearances: Use the gauge to accurately measure gaps and clearances between parts, ensuring a precise fit.

- Checking Alignment: Use the gauge to check the alignment of components during assembly.

- Creating Custom Parts: Use the gauge to measure and mark materials for creating custom parts.

“A beam profile gauge is like a surgeon’s scalpel for car modelers,” says renowned model maker, Robert Johnson. “It allows for precise and controlled manipulation of materials, resulting in a more refined and realistic final product.” Another expert, Maria Garcia, adds, “The key is consistency. Always calibrate your gauge and take multiple measurements to ensure accuracy.”

In conclusion, the beam profile gauge tool is indispensable for car modeling, enabling precise measurements and contributing to a higher-quality finished product. By understanding the different types of gauges, mastering their use, and incorporating advanced techniques, you can elevate your car modeling skills and create stunning, accurate replicas. Remember, choosing the right beam profile gauge tool is essential for achieving the desired level of precision in your car modeling projects.

FAQ

- What is the best type of beam profile gauge tool for beginners?

- How often should I calibrate my beam profile gauge tool?

- Can I use a beam profile gauge tool to measure curved surfaces?

- What are some common mistakes to avoid when using a beam profile gauge tool?

- Where can I buy a high-quality beam profile gauge tool?

- What is the difference between a digital and a dial caliper?

- How do I care for and maintain my beam profile gauge tool?

Need assistance? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 910 Cedar Lane, Chicago, IL 60605, USA. We have a 24/7 customer support team ready to help.

Leave a Reply