Cutting car panels is a crucial aspect of auto body repair and modification. Whether you’re patching rust, replacing damaged sections, or undertaking custom fabrication, choosing the Best Tool For Cutting Car Panels can significantly impact the quality, efficiency, and safety of your work. This guide will explore the various options available, helping you make an informed decision based on your specific needs and project requirements. After reading this, you will understand which tool is the best tool for cutting car panels for your particular project.

Understanding Your Cutting Needs

Before diving into the tools themselves, it’s essential to assess your project’s specific requirements. What type of metal are you cutting? How thick is the panel? What level of precision do you need? Are you working in a confined space? Answering these questions will help narrow down your choices. For instance, a nibbler might be sufficient for thin sheet metal, while an air saw or cut-off wheel is necessary for thicker gauge steel. If precision is paramount, an electric shears or plasma cutter might be the ideal choice. Learn about the best tool for cutting car body panels here.

What are the different types of car panel cutting tools?

Several tools can be employed for cutting car panels, each with its own advantages and disadvantages. These include nibblers, air saws, cut-off wheels, electric shears, plasma cutters, and reciprocating saws.

Which tool is best for cutting thin sheet metal?

Nibblers and electric shears are excellent choices for cutting thin sheet metal due to their maneuverability and clean cuts.

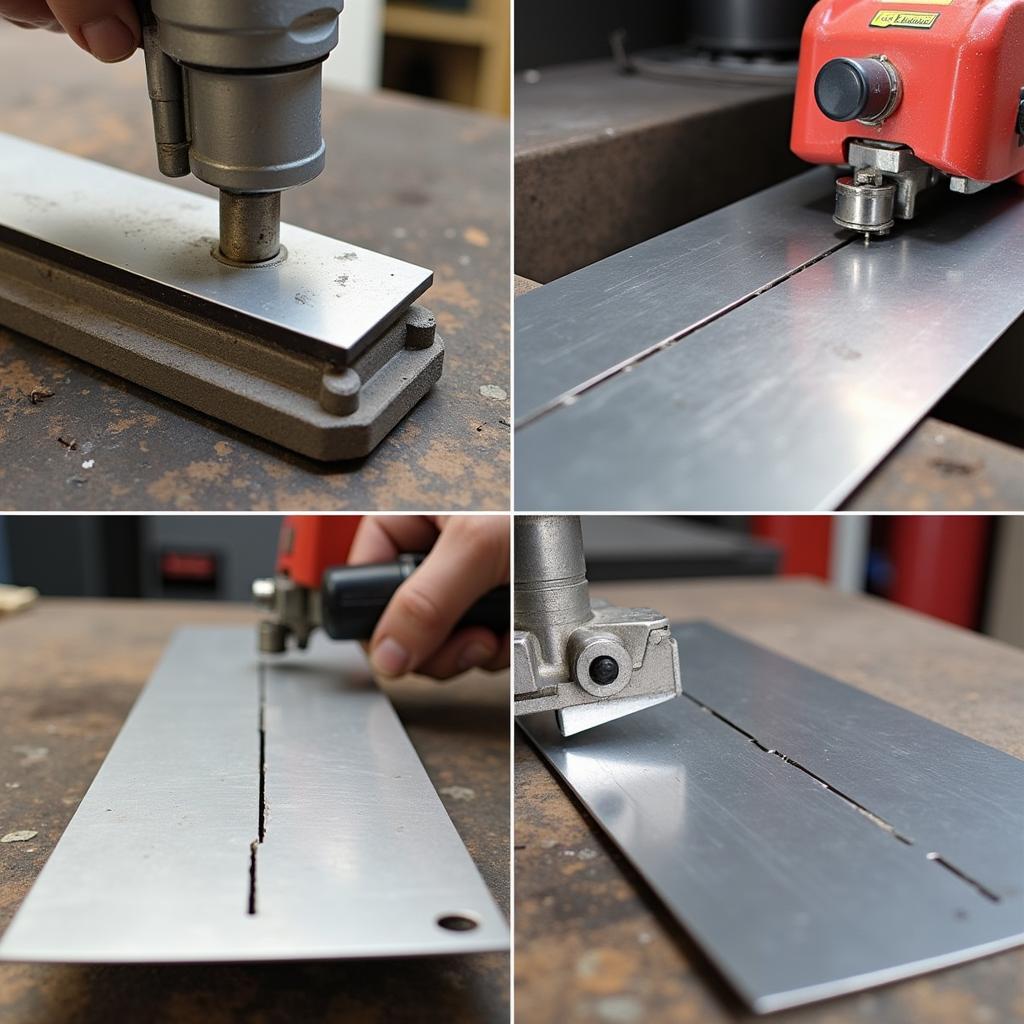

Nibbler and Electric Shears Cutting Thin Sheet Metal

Nibbler and Electric Shears Cutting Thin Sheet Metal

Exploring the Best Tools for Cutting Car Panels

Let’s delve into the specifics of each tool, considering their strengths, weaknesses, and best applications.

Nibblers

Nibblers are versatile tools ideal for cutting thin sheet metal. They work by “nibbling” away small pieces of metal, creating a relatively clean cut with minimal distortion. They are particularly useful for making curved cuts and working in tight spaces.

Air Saws and Cut-Off Wheels

Air saws and cut-off wheels are powerful tools capable of cutting through thicker gauge steel. Air saws offer more control for intricate cuts, while cut-off wheels provide rapid cutting action for straight lines. However, both generate significant heat and sparks, requiring appropriate safety precautions.

Electric Shears

Electric shears offer a balance between power and precision. They are suitable for cutting various thicknesses of sheet metal and provide clean, straight cuts. They are less noisy than air saws and generate less heat.

Plasma Cutters

Plasma cutters are high-powered tools that use a superheated, ionized gas to cut through metal. They are incredibly efficient for cutting thick materials but require a higher level of skill and investment.

Reciprocating Saws

Reciprocating saws, often referred to as Sawzalls, are versatile tools suitable for a variety of cutting tasks, including car panels. While not as precise as some other options, their aggressive cutting action makes them effective for removing damaged sections or making rough cuts. Check out the best brand for car tools for more information.

Choosing the Right Tool for Your Project

Choosing the right tool involves considering factors like material thickness, desired cut quality, budget, and experience level. For occasional DIY repairs, a nibbler or electric shears might suffice. Professionals undertaking complex restorations or modifications might require a combination of tools, including air saws, cut-off wheels, and plasma cutters. A car dash tool kit might contain some of these tools.

How do I ensure safety when cutting car panels?

Always wear appropriate safety gear, such as eye protection, gloves, and hearing protection. Ensure proper ventilation when working with tools that generate fumes or dust. Review the manufacturer’s instructions carefully before operating any tool.

“Safety is paramount when working with cutting tools. Always prioritize proper safety procedures and use the correct personal protective equipment,” advises John Miller, a seasoned auto body repair specialist.

Conclusion

Selecting the best tool for cutting car panels is essential for achieving professional results. By understanding the different types of tools available, their strengths and limitations, and the specific requirements of your project, you can make an informed decision that enhances your efficiency, safety, and overall outcome. Remember to factor in the car body repair tools price when making your decision. Ultimately, the best tool is the one that best suits your needs and allows you to achieve your desired results safely and effectively. What are the what tools do you need to detail a car?

“Investing in quality tools is an investment in your work. Choose wisely, and your projects will reflect that investment,” adds Maria Sanchez, an expert in automotive customization.

FAQ

- What is the best tool for cutting curved lines in car panels?

- Which tool offers the fastest cutting speed for straight lines?

- What safety precautions should I take when using a plasma cutter?

- What is the most versatile tool for cutting different types of car panels?

- What is the most affordable option for occasional DIY car panel cutting?

- Which tool is best for cutting thick steel panels?

- How do I choose the correct blade for my air saw or reciprocating saw?

For further information on car diagnostics and repair, explore other articles on our website. You might also be interested in topics like choosing the right welding equipment or understanding different types of automotive paint.

Need help? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 910 Cedar Lane, Chicago, IL 60605, USA. Our customer service team is available 24/7.

Leave a Reply