Clamp tools are indispensable for any car enthusiast or professional mechanic. Whether you’re a seasoned pro or a weekend warrior, understanding the various types of clamp tools, their applications, and how to use them effectively is crucial for tackling a range of automotive tasks. From brake repairs to bodywork and beyond, the right clamp can make all the difference.

Types of Clamp Tools for Automotive Applications

There’s a whole world of clamps out there, each designed for specific tasks. Let’s break down the most common types you’ll encounter in the automotive world:

- C-Clamps: These versatile clamps are ideal for holding parts together during gluing, welding, or other assembly tasks. Their simple design and adjustable screw mechanism make them easy to use and adaptable to various situations.

- Screw Clamps (G-Clamps): Similar to C-clamps, screw clamps offer a wider opening capacity, making them suitable for larger projects. They are commonly used in woodworking and metalworking, but also find application in automotive repair for holding body panels or other large components.

- Spring Clamps: These handy clamps are quick and easy to use with a simple spring mechanism. They are perfect for light-duty tasks and holding materials temporarily.

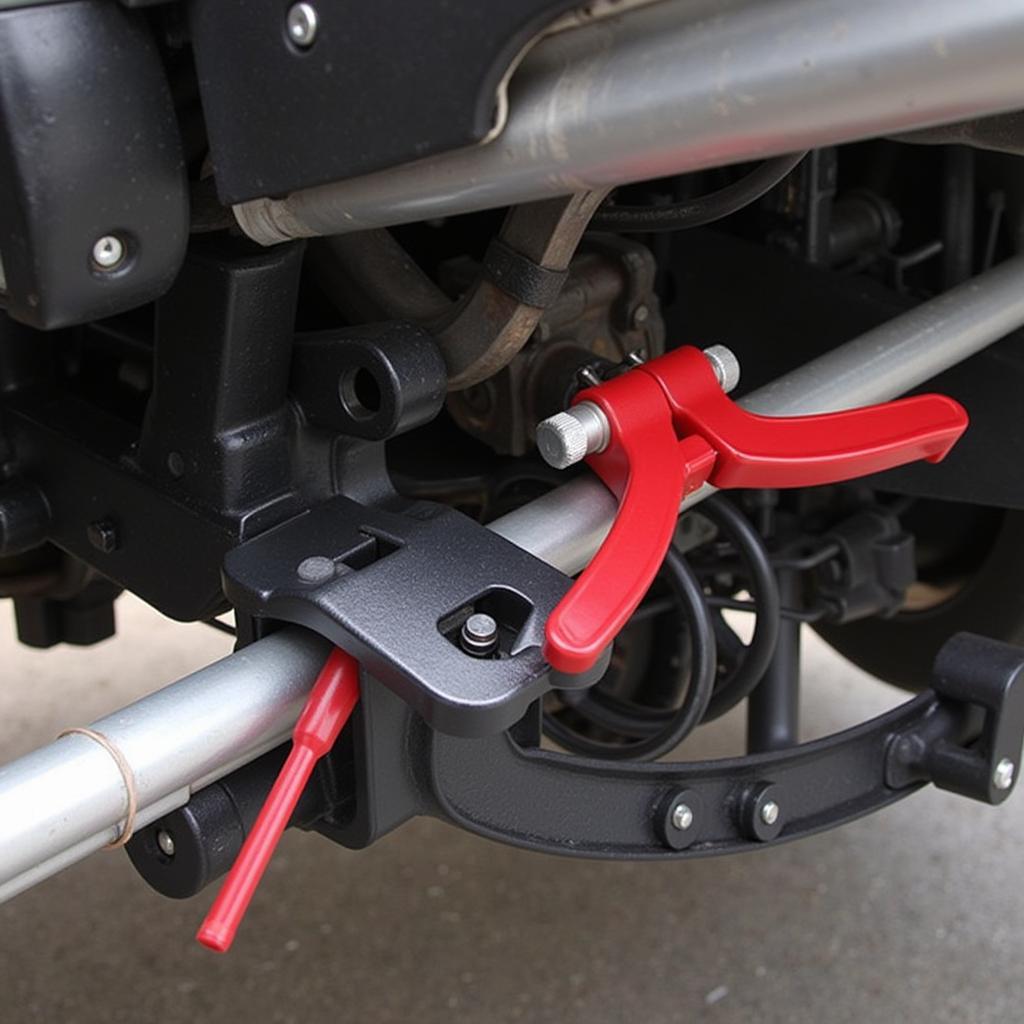

- Quick-Release Bar Clamps: Offering fast and efficient clamping, these tools utilize a trigger mechanism for quick adjustments. Their wide jaws and strong clamping force make them suitable for various automotive tasks, including holding body panels, securing workpieces during fabrication, and more.

- Hose Clamps: Specifically designed for securing hoses and pipes, these clamps come in various sizes and materials. They are essential for preventing leaks and ensuring proper fluid flow within a vehicle’s various systems.

C-Clamp Holding Car Parts During Repair

C-Clamp Holding Car Parts During Repair

Choosing the Right Clamp Tool for the Job

With so many options available, how do you choose the right clamp tool for your specific needs? Consider these factors:

- Material: The material of the clamp will determine its durability and suitability for certain tasks. Steel clamps are strong and durable, while plastic clamps are lighter and more resistant to corrosion.

- Size and Capacity: The size of the clamp should be appropriate for the size of the objects you are working with. Consider the opening capacity and the depth of the clamp’s throat.

- Clamping Force: The required clamping force depends on the application. Delicate tasks require lighter pressure, while heavy-duty projects demand a stronger grip.

- Specific Features: Some clamps offer specialized features, such as swivel pads, quick-release mechanisms, or deep throats, which can enhance their functionality for specific automotive applications. For instance, when working with brake pipes, the brake pipe flaring tool euro car parts might be necessary.

Various Clamp Tools for Automotive Repair

Various Clamp Tools for Automotive Repair

Using Clamp Tools Safely and Effectively

Safety is paramount when using any tool, and clamp tools are no exception. Follow these guidelines:

- Inspect the Clamp: Check for any damage or defects before each use.

- Protect the Workpiece: Use soft jaws or padding to prevent damage to the surfaces being clamped.

- Apply Even Pressure: Distribute the clamping force evenly to avoid warping or damaging the workpiece.

- Don’t Overtighten: Excessive tightening can damage the clamp or the workpiece.

If you are unsure which tools to use when disconnecting your car battery, you can refer to our guide on tools needed to disconnect car battery.

Maintaining Your Clamp Tools

Proper maintenance ensures the longevity and effectiveness of your clamp tools.

- Clean After Use: Remove any debris or residue from the clamp after each use.

- Lubricate Moving Parts: Periodically lubricate the screw mechanism or other moving parts to prevent rust and ensure smooth operation.

- Store Properly: Store clamps in a dry and organized manner to prevent damage. If you are looking to enhance your car repair skills, knowing about the best car frame repair tools can be very helpful.

Mechanic Using Clamp Tool on Car

Mechanic Using Clamp Tool on Car

Conclusion

Clamp tools are essential for any automotive project, from simple repairs to complex restorations. Choosing the right clamp and using it correctly can significantly enhance your efficiency and ensure a successful outcome. Understanding the various types of clamps available, their specific applications, and the importance of proper maintenance will empower you to tackle your automotive tasks with confidence. If you are dealing with car molding issues, check out our guide on car molding repair tools. For information about calipers and specialized tools, visit our article on what cars have calipers that need a special tool.

FAQ

- What type of clamp is best for holding car body panels together during welding?

- Can I use a C-clamp for holding hoses?

- How do I prevent damage to the workpiece when using a clamp?

- What is the difference between a C-clamp and a G-clamp?

- How often should I lubricate my clamp tools?

- Are there specific clamps for brake repairs?

- Where can I find high-quality clamp tools for automotive use?

Need help with your car diagnostics? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 910 Cedar Lane, Chicago, IL 60605, USA. Our customer service team is available 24/7.

Leave a Reply