A Crick Tool Care Kit is a crucial investment for any automotive professional or DIY enthusiast. Maintaining your diagnostic tools ensures accurate readings, prolongs their lifespan, and ultimately saves you time and money. This comprehensive guide will delve into the importance of a crick tool care kit, what it should contain, and best practices for tool maintenance.

Why You Need a Crick Tool Care Kit

Diagnostic tools, especially those used for tasks like measuring crick angles or assessing suspension components, are susceptible to wear and tear, damage, and calibration drift. A dedicated care kit helps address these issues, ensuring your tools are always ready for accurate and reliable diagnoses. Regular maintenance using a crick tool care kit can prevent costly repairs or replacements down the line.

Building Your Ideal Crick Tool Care Kit

A well-rounded crick tool care kit should encompass several key components. Firstly, cleaning supplies are essential. These include specialized cleaning solutions, brushes, and microfiber cloths to remove dirt, grease, and debris. Calibration tools, specific to your crick tools, are vital for maintaining accuracy. Protective cases or storage solutions safeguard your investment from damage and environmental factors. Finally, lubrication oils or greases ensure smooth operation and prevent corrosion.

Essential Components of a Crick Tool Care Kit:

- Cleaning Solutions: Choose non-corrosive, specialized cleaning agents designed for automotive diagnostic tools.

- Brushes: Soft-bristled brushes are ideal for removing dirt and grime without scratching delicate surfaces.

- Calibration Tools: Ensure your calibration tools are compatible with your specific crick tools and follow manufacturer instructions.

- Protective Cases: Durable cases protect your tools from impacts, dust, and moisture.

- Lubrication: Use appropriate lubricants to prevent friction and corrosion.

Best Practices for Crick Tool Care

Maintaining your crick tools isn’t just about having the right kit; it’s about implementing proper practices. Always consult your tool manufacturer’s instructions for specific cleaning and calibration procedures. After each use, clean your tools thoroughly and inspect them for any signs of damage. Store your tools in their protective cases in a clean, dry environment. Regular calibration is crucial, especially if you notice any discrepancies in readings.

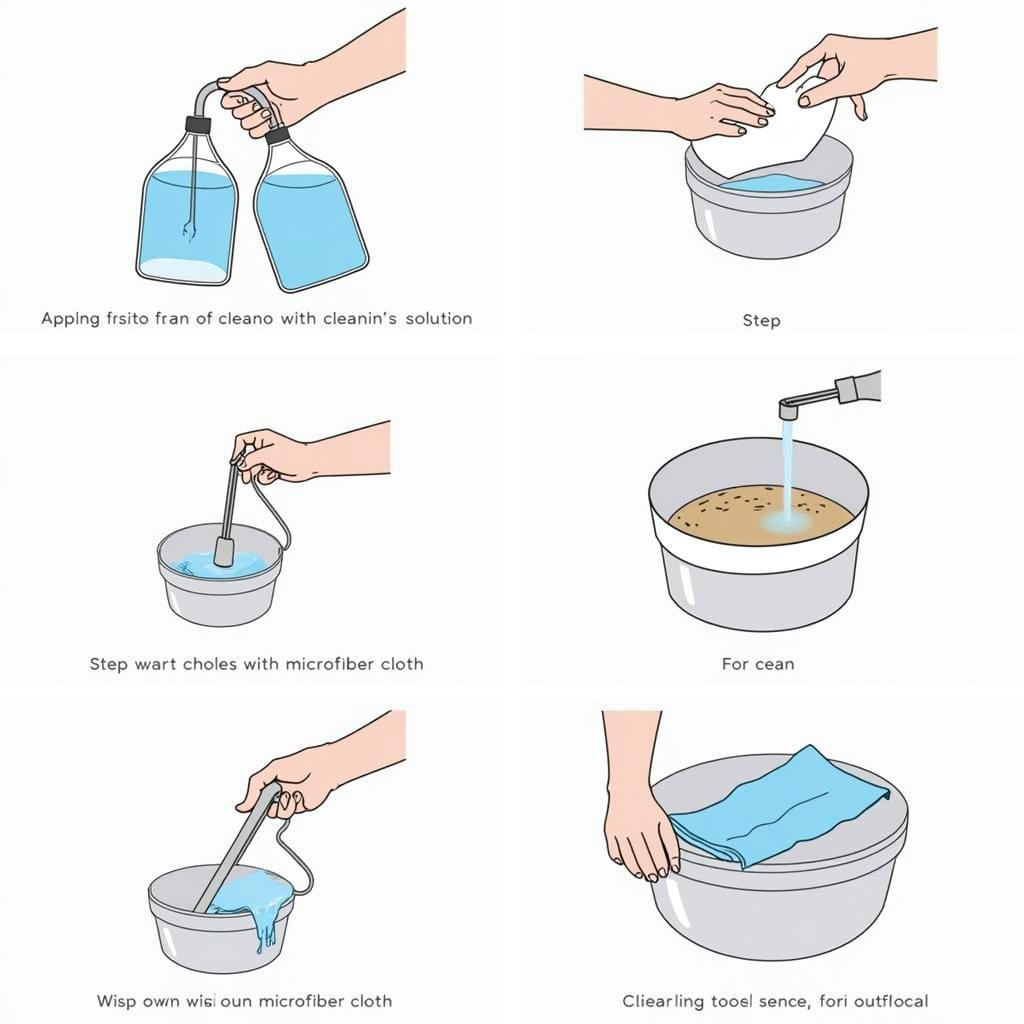

Step-by-Step Crick Tool Cleaning Process

Step-by-Step Crick Tool Cleaning Process

Simple Steps for Maintaining Your Crick Tools:

- Clean After Every Use: This prevents build-up and ensures accuracy.

- Inspect for Damage: Identify any potential issues early on.

- Calibrate Regularly: Follow the manufacturer’s recommended calibration schedule.

- Store Properly: Protect your investment from environmental factors.

The Importance of Regular Calibration

Calibration is often overlooked, but it’s essential for ensuring the accuracy of your crick tools. Over time, tools can drift from their calibrated settings due to regular use, impacts, or temperature changes. Regular calibration, as per the manufacturer’s recommendations, guarantees consistent and reliable measurements, crucial for making informed diagnostic decisions.

“Regular calibration is not just a recommendation, it’s a necessity for reliable diagnostics,” says Robert Johnson, Senior Automotive Diagnostic Technician at Precision Automotive Services. “A slight calibration error can lead to misdiagnosis and unnecessary repairs.”

Correct Crick Tool Calibration Procedure

Correct Crick Tool Calibration Procedure

Conclusion

Investing in and maintaining a crick tool care kit is essential for any automotive professional or serious DIYer. By following the best practices outlined in this guide and using a comprehensive care kit, you can ensure the longevity, accuracy, and reliability of your crick tools, ultimately saving you time and money in the long run. Remember, accurate diagnostics start with properly maintained tools.

FAQ

- What is the most important component of a crick tool care kit?

- How often should I calibrate my crick tools?

- Can I use household cleaners on my crick tools?

- Where should I store my crick tool care kit?

- What are the signs that my crick tools need calibration?

- What type of lubrication should I use for my crick tools?

- Where can I find calibration tools for my specific crick tools?

“A well-maintained tool is a reflection of a professional,” adds Maria Sanchez, Lead Calibration Specialist at Auto Diagnostics Inc. “Taking care of your tools demonstrates a commitment to accuracy and quality workmanship.”

For further assistance, please contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 910 Cedar Lane, Chicago, IL 60605, USA. Our customer support team is available 24/7.

Leave a Reply