Diagnostic point to point measuring is an essential aspect of modern automotive collision repair. This technique utilizes precise measurements to determine the extent of damage to a vehicle’s frame or chassis, allowing technicians to restore it to its original factory specifications. A key tool in this process is the car-o-liner tool, a sophisticated piece of equipment that has revolutionized the way collision damage is assessed and repaired.

Understanding Diagnostic Point to Point Measuring

Before delving into the specifics of car-o-liner tools, it’s crucial to understand the importance of diagnostic point to point measuring. Unlike traditional methods that relied on visual inspections and rudimentary tools, this technique employs advanced technology to gather accurate data points across the vehicle’s structure. By comparing these measurements to the manufacturer’s database, technicians can identify even the slightest deviations that may indicate structural damage.

The Role of the Car-O-Liner Tool

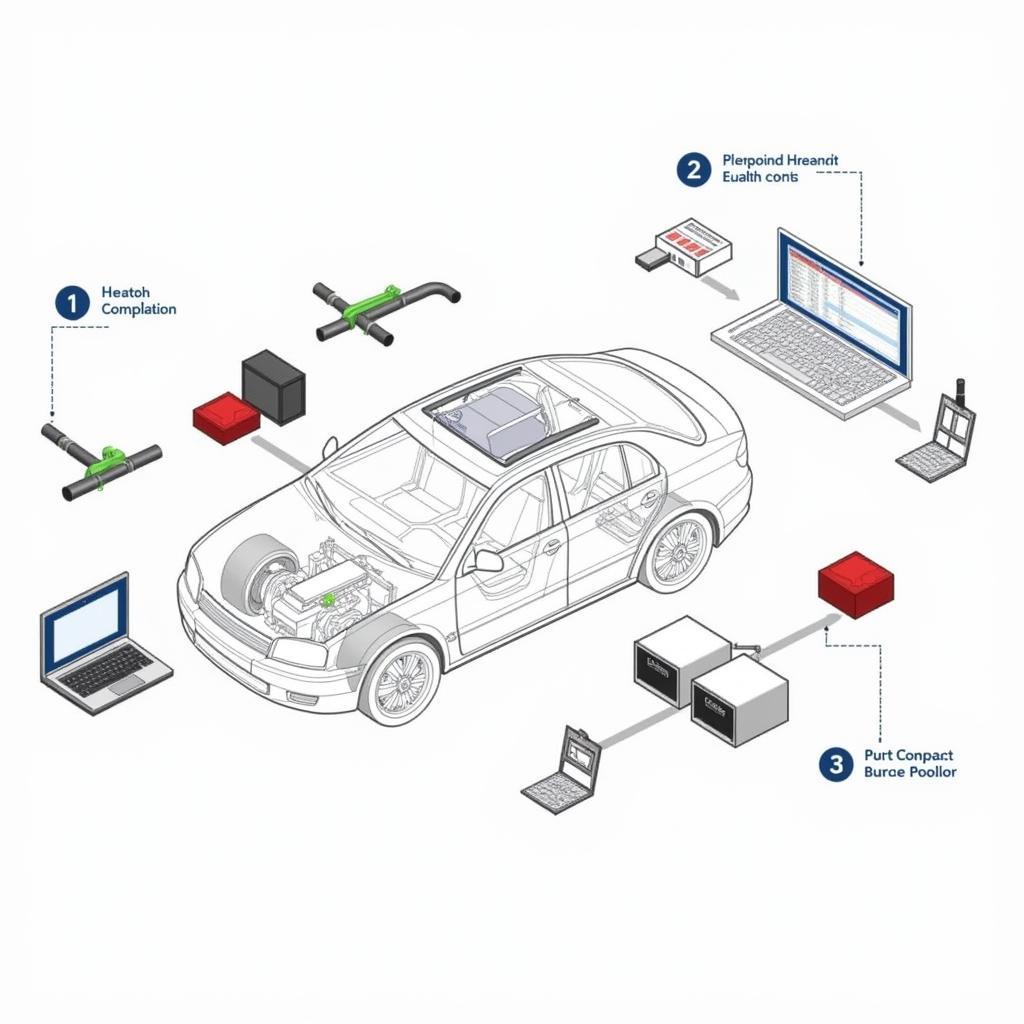

The car-o-liner tool plays a pivotal role in diagnostic point to point measuring. This sophisticated system typically consists of:

- Measuring Arms: These extendable arms with high-precision sensors attach to specific points on the vehicle’s chassis.

- Computer System: The heart of the system, processing the data gathered by the measuring arms and comparing it to the manufacturer’s specifications.

- Software: User-friendly software provides a visual representation of the measurements, highlighting any deviations from the norm.

Components of a car-o-liner tool

Components of a car-o-liner tool

Benefits of Using a Car-O-Liner Tool

The use of a car-o-liner tool in diagnostic point to point measuring offers numerous benefits for both automotive repair shops and vehicle owners:

- Increased Accuracy: The high-precision sensors ensure accurate measurements, eliminating guesswork and ensuring that the vehicle’s frame is restored to its original integrity.

- Time Savings: The automated system significantly reduces the time required for measuring, allowing technicians to focus on the actual repair process.

- Improved Repair Quality: Accurate measurements translate to a higher quality repair, restoring the vehicle’s safety, handling, and overall structural integrity.

- Enhanced Safety: By ensuring the vehicle’s frame is repaired to factory specifications, the risk of future structural failures is minimized, enhancing safety for drivers and passengers.

How Does Diagnostic Point to Point Measuring Work?

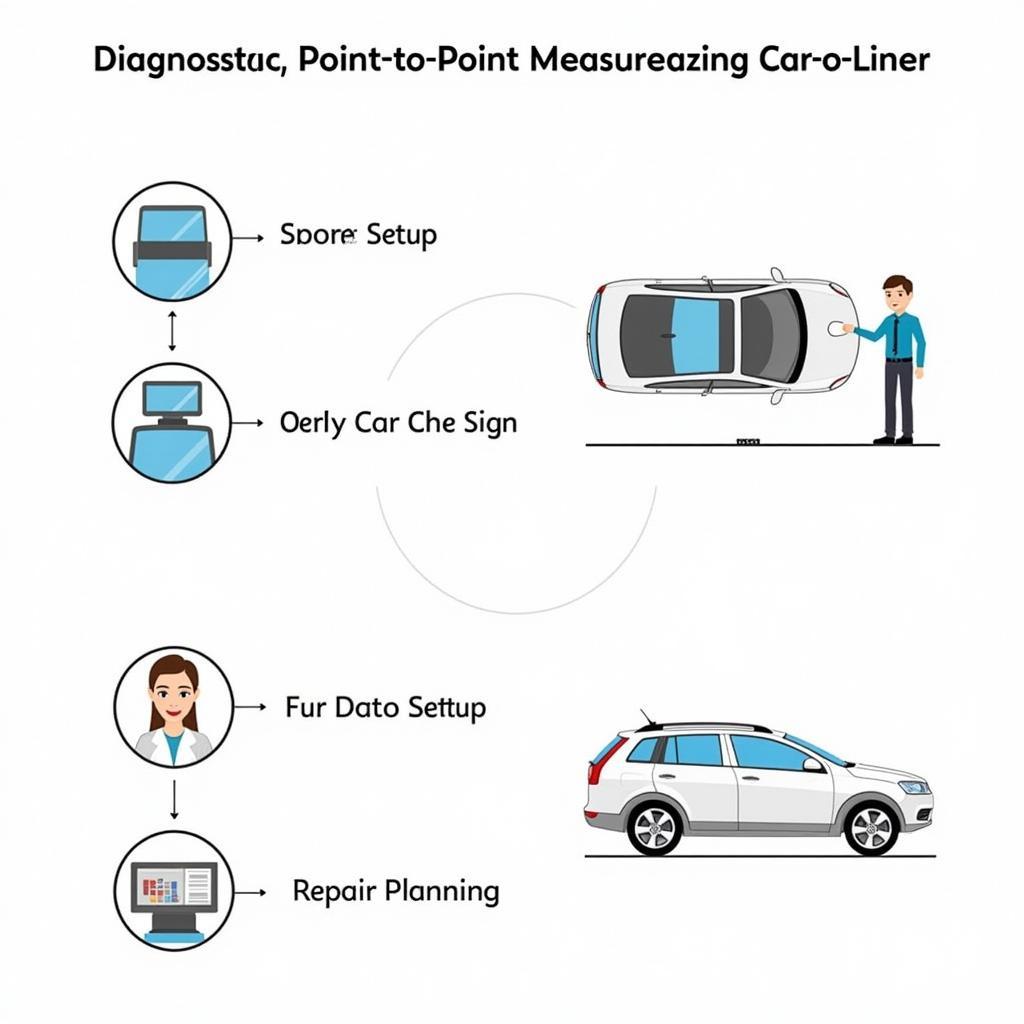

The process of diagnostic point to point measuring using a car-o-liner tool typically involves the following steps:

- Vehicle Setup: The damaged vehicle is securely mounted on a lift within the car-o-liner system.

- Data Point Measurement: The technician attaches the measuring arms to specific reference points on the vehicle’s chassis.

- Data Analysis: The system gathers data from the sensors and transmits it to the computer, where specialized software compares it to the manufacturer’s database.

- Damage Assessment: The software generates a visual representation of the measurements, highlighting any deviations from the factory specifications.

- Repair Planning: Based on the data analysis, technicians develop a comprehensive repair plan to address the identified structural damage.

Diagnostic point-to-point measuring process in action

Diagnostic point-to-point measuring process in action

Choosing the Right Car-O-Liner Tool

Selecting the appropriate car-o-liner tool for your automotive repair shop depends on various factors, including:

- Shop Size and Volume: Consider the available workspace and the number of vehicles typically repaired.

- Budget: Car-o-liner tools come in a range of prices, so it’s essential to choose one that aligns with your budget.

- Features and Capabilities: Different models offer various features and capabilities, so select one that meets your specific repair needs.

“Investing in a high-quality car-o-liner tool is essential for any automotive repair shop serious about providing top-notch collision repair services,” says John Miller, a seasoned automotive engineer with over 20 years of experience. “It’s an investment that pays dividends in terms of accuracy, efficiency, and customer satisfaction.”

Conclusion

Diagnostic point to point measuring using a car-o-liner tool has transformed the automotive collision repair industry. This sophisticated technology enables technicians to accurately assess structural damage, ensuring that vehicles are repaired to their original factory specifications. By investing in a car-o-liner tool, automotive repair shops demonstrate their commitment to providing high-quality repairs, enhancing vehicle safety and customer satisfaction.

Leave a Reply