Maintaining your air tools is crucial for their longevity and optimal performance. Whether you’re a professional mechanic or a DIY enthusiast, knowing How To Care For Air Tools will save you money and frustration in the long run. Proper maintenance ensures consistent power, reduces downtime, and extends the life of your valuable equipment.

The Importance of Regular Air Tool Maintenance

Just like any other power tool, air tools require regular maintenance to function correctly. Neglecting these essential tasks can lead to premature wear and tear, reduced efficiency, and ultimately, costly repairs or replacements. By following a few simple steps, you can keep your air tools in top condition for years to come. A well-maintained air tool is a safe air tool.

Essential Steps for Caring for Your Air Tools

Lubrication is Key

Lubrication is arguably the most critical aspect of air tool maintenance. Without proper lubrication, internal components can grind against each other, causing excessive friction and heat, leading to premature wear. Always consult your air tool’s manual for the manufacturer’s recommended lubricant and lubrication schedule. Generally, adding a few drops of air tool oil before each use is a good practice. Some tools might have specific lubrication points, so be sure to identify and utilize them. Remember, over-lubrication can also be detrimental, so avoid using too much oil.

“Regular lubrication is the lifeblood of your air tools,” says John Miller, a seasoned automotive technician with over 20 years of experience. “A few drops of oil can significantly extend the lifespan of your tools and prevent costly repairs.”

Keeping it Clean

Dust, debris, and moisture are the enemies of air tools. After each use, take a few minutes to clean your air tools with a hair stylist career tools blow gun or a soft brush. This simple step will prevent buildup that can clog air passages and hinder performance. For more stubborn debris, use a specialized air tool cleaner. If your air tool is used in a particularly dusty environment, consider using an inline air filter to prevent contaminants from entering the tool in the first place.

Proper Storage

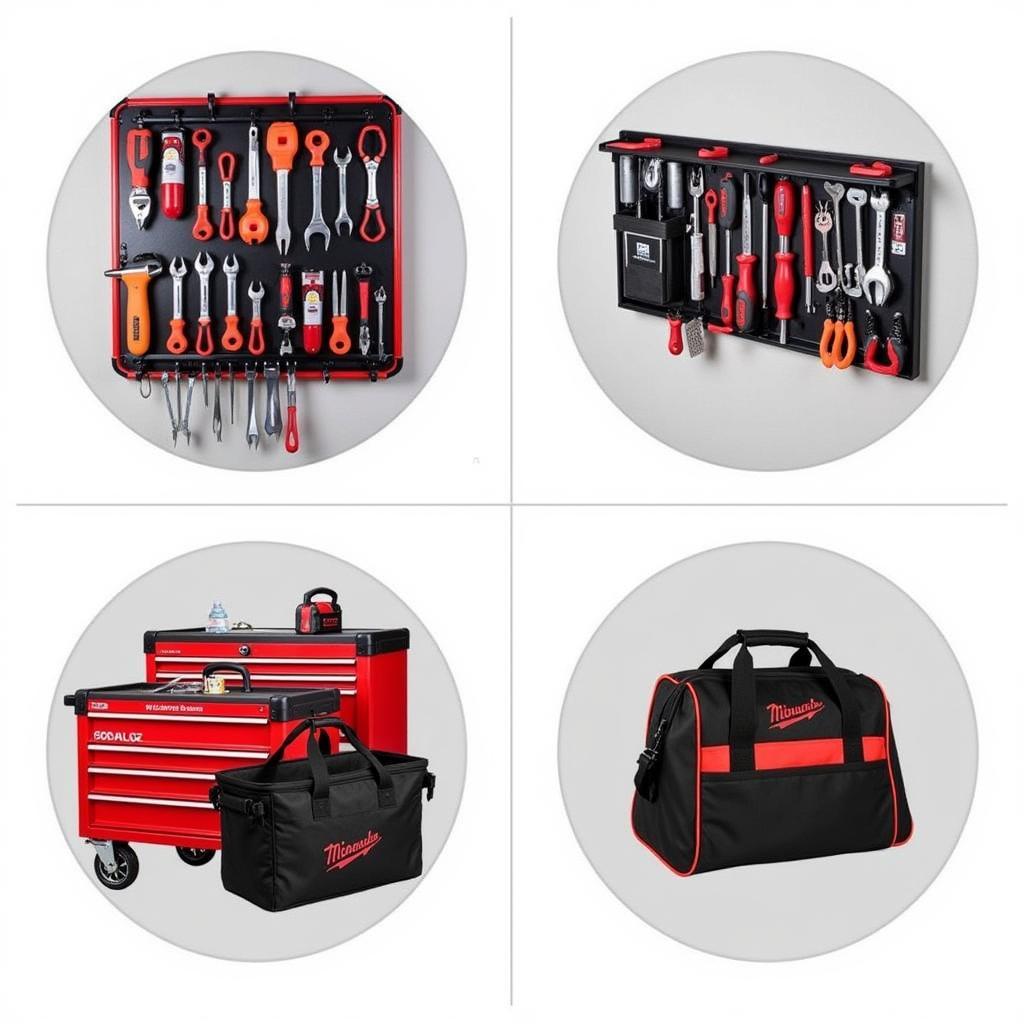

How you store your air tools can significantly impact their longevity. Always store your air tools in a clean, dry place, away from extreme temperatures and humidity. If possible, store them in a dedicated toolbox or cabinet to protect them from dust and damage. Before storing your tools for an extended period, be sure to lubricate them properly to prevent corrosion.

Effective Air Tool Storage Solutions

Effective Air Tool Storage Solutions

Inspecting for Wear and Tear

Regularly inspect your air tools for signs of wear and tear. Check for cracks, leaks, and loose fittings. Replace any damaged parts immediately to prevent further damage and ensure safe operation. Pay close attention to hoses and fittings, as these are common points of failure. Also, ensure the air inlet is clear of obstructions.

What type of oil should I use for my air tools?

Always use air tool oil specifically designed for pneumatic tools. Using the wrong type of oil can damage the internal seals and components.

How often should I lubricate my air tools?

A good rule of thumb is to add a few drops of oil before each use. For heavier use, more frequent lubrication might be necessary. Consult your tool’s manual for specific recommendations.

How do I prevent moisture buildup in my air lines?

Using an inline air dryer or moisture trap can significantly reduce the amount of moisture that reaches your air tools.

“Preventive maintenance is always cheaper than reactive repairs,” advises Sarah Johnson, a mechanical engineer specializing in pneumatic systems. “Taking the time to care for your air tools will save you time and money in the long run.”

Conclusion

Properly caring for your air tools is an investment that pays off in terms of performance, longevity, and safety. By following these simple steps—lubrication, cleaning, proper storage, and regular inspection—you can keep your air tools running smoothly for years to come. Remember, a well-maintained tool is a productive tool. Taking care of your air tools, like choosing the right hair care hot tools or automating tasks with an automate client care tools list, requires diligence and attention. Now you’re equipped with the knowledge on how to care for air tools, keeping them running smoothly and extending their lifespan.

FAQ

- What is the most important aspect of air tool maintenance?

- How can I clean my air tools effectively?

- Where should I store my air tools?

- What should I look for when inspecting my air tools?

- What type of oil should I use?

- How often should I drain my air compressor tank?

- Can I use regular motor oil for my air tools?

For further insights, consider exploring our resources on hair care fragrance tools and calista tools hair care arewview.

Need help with your car diagnostic tools? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 910 Cedar Lane, Chicago, IL 60605, USA. Our customer service team is available 24/7.

Leave a Reply