Building a fast pinewood derby car doesn’t always require a workshop full of power tools. You can create a competitive racer using simple hand tools and a bit of ingenuity. This guide will show you How To Make A Pinewood Derby Car Without Power Tools, focusing on techniques that prioritize speed and performance.

Building a pinewood derby car with hand tools can be a rewarding experience, allowing for greater control and precision. Let’s explore how you can achieve this. One of the first steps is understanding the importance of a smooth and aerodynamic body. This can be achieved with careful sanding using progressively finer grits of sandpaper. Remember, a well-sanded car is a fast car! This guide will help you navigate these crucial steps, ensuring your car is ready to race. You can find more helpful information on essential car tools on our page about the most important tools to fix a car.

Shaping the Body: Hand Tools are Your Friends

Shaping the wood block into a sleek, aerodynamic car is key to minimizing drag and maximizing speed. While power tools can make this process faster, hand tools offer more control, allowing for precise shaping and fine details. A rasp, a woodworking file with a coarse surface, is excellent for removing larger amounts of wood and shaping the initial form of your car. Follow this with sandpaper, starting with a coarser grit and gradually moving to finer grits for a smooth finish.

Remember to focus on creating a low-profile design that minimizes wind resistance. Consider adding subtle curves and angles to further enhance aerodynamics. Testing different shapes can reveal which design performs best. This hands-on approach allows you to truly understand the relationship between shape and speed. For ideas on specialized tools, you can visit our page about tools for cutting pinewood derby cars.

Axle Preparation: The Key to a Smooth Ride

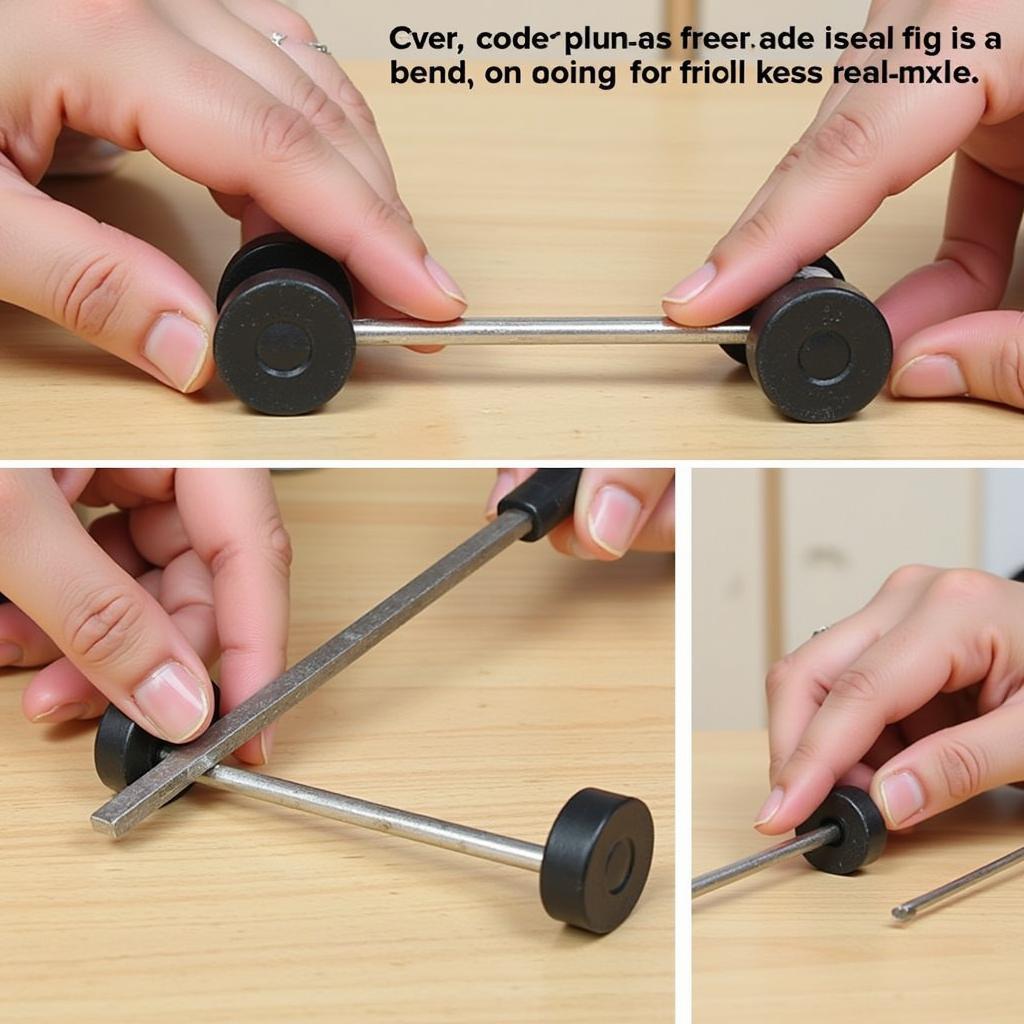

Axle preparation is crucial for reducing friction and ensuring a smooth, fast ride. Start by carefully inspecting the axles for any imperfections or burrs. Use a fine metal file to smooth any rough spots, ensuring the axles are perfectly straight and uniform. Polishing the axles with a metal polish can further reduce friction.

Straight Axles, Straight Track, Straight to the Finish Line

Ensuring your axles are perfectly straight is paramount to a fast and smooth run. A bent axle can create significant friction and hinder your car’s performance. You can check for straightness by rolling the axles on a flat surface. Any wobble indicates a bend that needs to be corrected.

Straightening pinewood derby car axles with a metal file

Straightening pinewood derby car axles with a metal file

Lubrication is the final step in axle preparation. Apply a small amount of graphite lubricant to the axles, ensuring they rotate freely within the axle slots. Proper lubrication significantly reduces friction, allowing your car to roll faster and farther. Looking for a comprehensive toolkit for your car projects? Check out our recommended car detail tool box.

Weight Placement: Balancing Act for Speed

Proper weight placement is essential for maximizing your car’s potential. Concentrating the weight towards the rear of the car helps maintain momentum on the downhill track. Use adhesive putty or lead weights to add weight, experimenting with different placements to find the optimal balance for your car’s design.

Finding the Sweet Spot for Maximum Speed

Finding the perfect weight placement requires experimentation. Start by placing the majority of the weight at the rear and gradually adjust its position until you find the sweet spot that delivers the fastest and most consistent runs. This process may involve multiple test runs and adjustments. Learn more about specialized cutting tools on our cut pinewood derby car oscillating tool page.

Placing weights strategically on a pinewood derby car for optimal performance

Placing weights strategically on a pinewood derby car for optimal performance

Conclusion: Winning without Power Tools

Building a competitive pinewood derby car without power tools is entirely achievable. With careful attention to detail, precise hand tool work, and strategic weight placement, you can create a car that is ready to race and win. Remember, the key to success lies in patience, precision, and a little bit of ingenuity. By following these steps, you’ll have a car that not only performs well but also reflects your craftsmanship and dedication. And if you’re looking for premium car tools, check out our selection of expensive car tools.

FAQ

-

What type of wood is best for a pinewood derby car?

- Softwoods like balsa or basswood are generally preferred due to their lightweight nature and ease of shaping.

-

What kind of lubricant is best for pinewood derby axles?

- Dry lubricants like graphite are recommended as they minimize dust and debris buildup.

-

How much weight should I add to my pinewood derby car?

- The maximum allowable weight is typically specified in the race rules, so be sure to check those guidelines.

-

How can I make my pinewood derby car more aerodynamic?

- Shaping the car into a streamlined, low-profile design minimizes wind resistance and improves aerodynamics.

-

What are some common mistakes to avoid when building a pinewood derby car?

- Common mistakes include using the wrong type of lubricant, improper weight placement, and neglecting to polish the axles.

-

Can I use household items for weight in my pinewood derby car?

- Yes, items like coins or fishing weights can be used, but ensure they are securely attached and the total weight doesn’t exceed the limit.

-

Where can I find more information about pinewood derby car building?

- Online forums, hobby shops, and scouting organizations are excellent resources for additional tips and guidance.

For any assistance, please contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 910 Cedar Lane, Chicago, IL 60605, USA. Our customer service team is available 24/7.

Leave a Reply