The IATF CARA NC (Non-Conformance) management tool is crucial for automotive suppliers aiming to comply with IATF 16949:2016. This guide answers frequently asked questions about the tool, offering valuable insights for both customers and businesses in the automotive industry.

Understanding the IATF CARA NC Management Tool

The IATF CARA NC management tool is a standardized process for handling non-conformances within the automotive supply chain. It provides a structured approach to identifying, documenting, analyzing, and correcting deviations from specified requirements. Effective NC management is essential for continuous improvement, customer satisfaction, and maintaining IATF 16949 certification.

Key Benefits of Using the IATF CARA NC Management Tool

Implementing the IATF CARA NC management tool offers several key benefits:

- Improved Quality: By systematically addressing non-conformances, the tool helps identify and eliminate root causes, leading to improved product and process quality.

- Enhanced Customer Satisfaction: A robust NC management system demonstrates a commitment to quality and helps build trust with customers.

- Compliance with IATF 16949: The tool ensures compliance with the requirements of IATF 16949:2016 related to non-conformance management.

- Reduced Costs: By preventing recurring non-conformances, the tool can reduce waste, rework, and warranty costs.

- Continuous Improvement: The data collected through the NC management process provides valuable insights for driving continuous improvement initiatives.

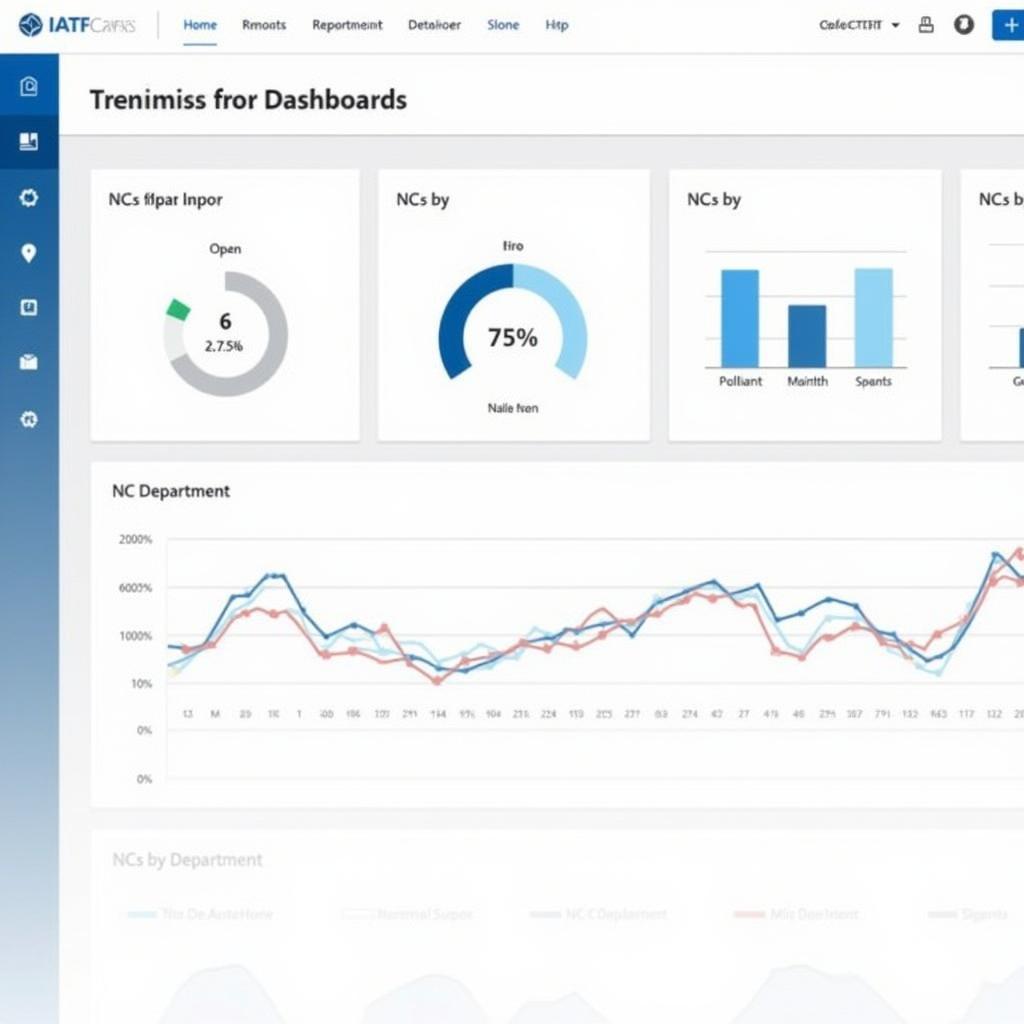

IATF CARA NC Management Tool Dashboard

IATF CARA NC Management Tool Dashboard

How Does the IATF CARA NC Management Tool Work?

The IATF CARA NC management tool typically involves the following steps:

- Identification: Non-conformances are identified through various sources, such as internal audits, customer complaints, and process monitoring.

- Documentation: Detailed information about the non-conformance is documented, including the nature of the deviation, the affected products or processes, and the date of occurrence.

- Analysis: Root cause analysis techniques are used to determine the underlying causes of the non-conformance.

- Corrective Action: Corrective actions are implemented to address the root causes and prevent recurrence of the non-conformance.

- Verification: The effectiveness of the corrective actions is verified through follow-up activities.

- Closure: The NC is closed once the corrective actions have been implemented and verified.

Common Challenges in Implementing the IATF CARA NC Management Tool

While the IATF CARA NC management tool offers significant advantages, organizations may face certain challenges during implementation:

- Lack of Training: Employees need to be adequately trained on the proper use of the tool and the associated procedures.

- Resistance to Change: Some employees may resist adopting new processes or procedures.

- Data Management: Effective data management is crucial for tracking and analyzing NCs.

- Integration with other Systems: The tool needs to be seamlessly integrated with other existing systems, such as quality management systems.

IATF CARA NC Management Tool Best Practices

- Establish clear roles and responsibilities: Define who is responsible for identifying, documenting, analyzing, and correcting NCs.

- Use a standardized process: Implement a consistent process for handling all NCs.

- Focus on root cause analysis: Identify and address the underlying causes of NCs to prevent recurrence.

- Use data to drive improvement: Track and analyze NC data to identify trends and areas for improvement.

- Communicate effectively: Keep all stakeholders informed about the status of NCs and corrective actions.

“Effective NC management is not just about fixing problems; it’s about learning from them and preventing them from happening again.” – John Smith, Senior Quality Engineer at Automotive Solutions Inc.

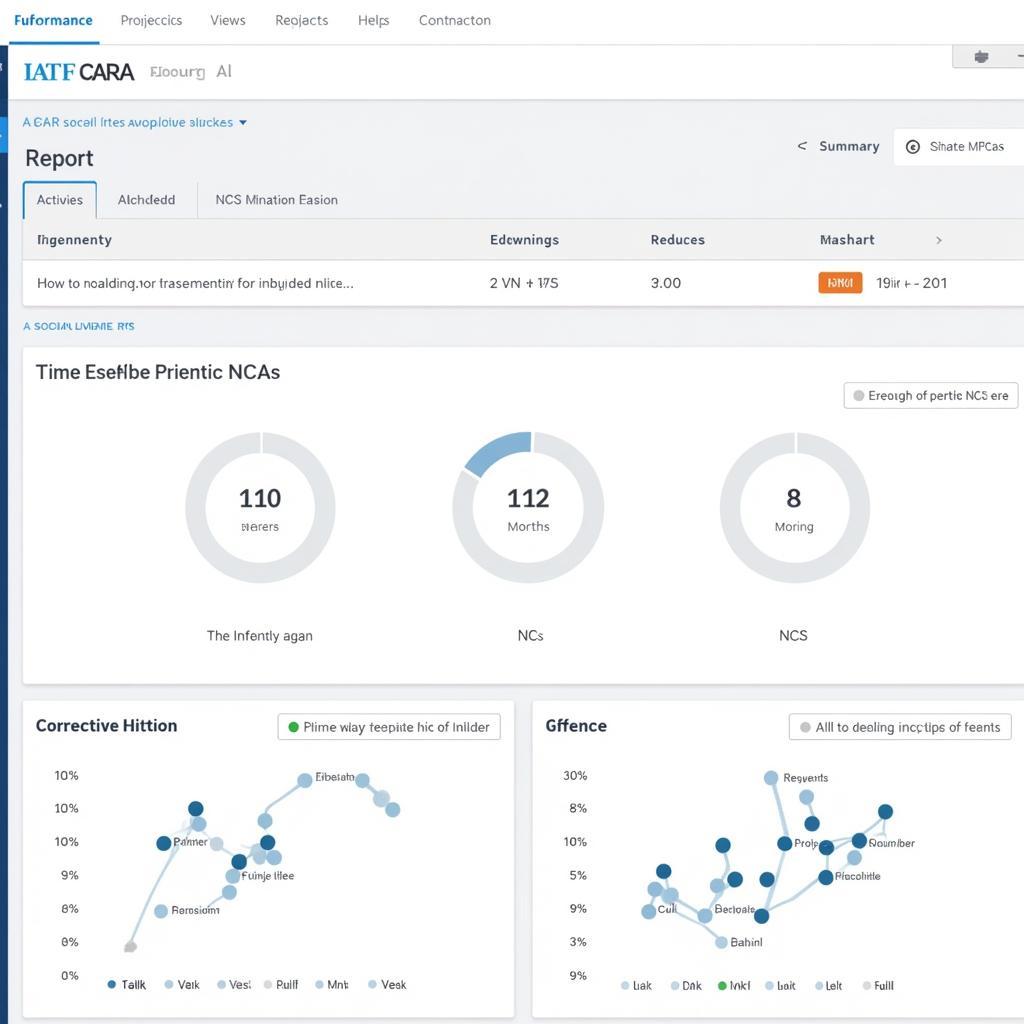

IATF CARA NC Management Tool Reporting

IATF CARA NC Management Tool Reporting

Conclusion

The IATF CARA NC management tool is a powerful resource for automotive suppliers seeking to improve quality, enhance customer satisfaction, and maintain IATF 16949:2016 compliance. By implementing the tool effectively and following best practices, organizations can achieve significant benefits and drive continuous improvement within their operations.

FAQ

- What is the IATF CARA NC management tool? It’s a standardized process for handling non-conformances in the automotive supply chain.

- Why is NC management important? It ensures continuous improvement, customer satisfaction, and IATF 16949 compliance.

- How does the tool work? It involves identifying, documenting, analyzing, correcting, verifying, and closing NCs.

- What are the benefits of using the tool? Improved quality, enhanced customer satisfaction, reduced costs, and continuous improvement.

- What are the common challenges? Lack of training, resistance to change, data management, and system integration.

Need assistance with your car diagnostic needs? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 910 Cedar Lane, Chicago, IL 60605, USA. We offer 24/7 customer support.

Leave a Reply