The Lisle 16750 car valve spring compressor tool is a crucial piece of equipment for any mechanic working on engine valve repairs or replacements. Understanding its functionality, proper usage, and the benefits it offers can significantly improve your efficiency and the quality of your work. This comprehensive guide will delve into everything you need to know about the Lisle 16750, from its basic operation to advanced techniques and best practices.

Understanding the Lisle 16750 Car Valve Spring Compressor Tool

The Lisle 16750 is an overhead valve spring compressor designed to compress valve springs safely and efficiently without removing the cylinder head from the engine block. This saves considerable time and effort, making it an invaluable tool for both professional mechanics and DIY enthusiasts. It allows for the easy removal and installation of valve keepers, retainers, and springs, streamlining the entire valve service process.

Why Choose the Lisle 16750?

- Efficiency: Compress valve springs quickly and easily, reducing overall repair time.

- Safety: Provides a secure grip on the valve spring, minimizing the risk of slippage and potential injury.

- Versatility: Compatible with a wide range of engines, making it a versatile addition to any toolbox.

- Durability: Constructed from high-quality materials, ensuring long-lasting performance and reliability.

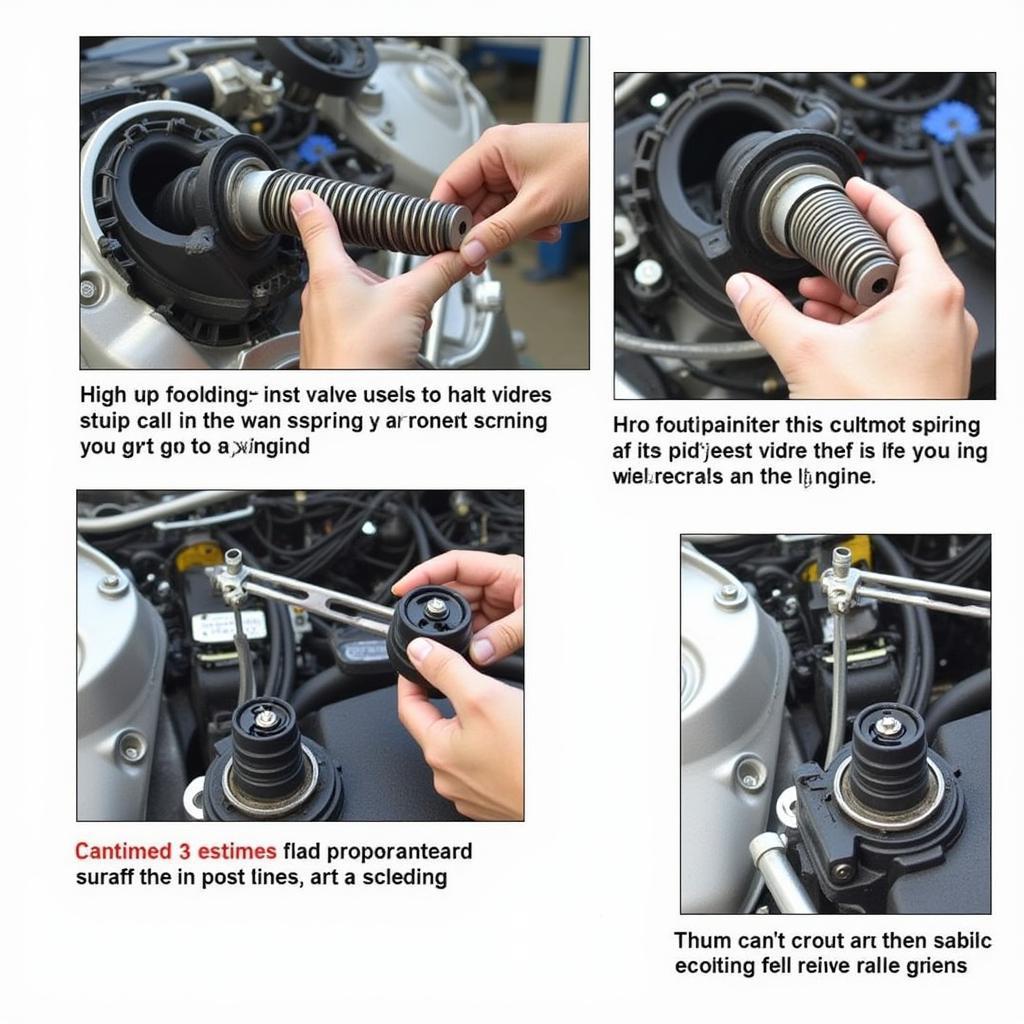

Lisle 16750 Valve Spring Compressor Tool in Action

Lisle 16750 Valve Spring Compressor Tool in Action

How to Use the Lisle 16750 on the Car Valve Spring Compressor Tool

Using the Lisle 16750 might seem daunting at first, but with a bit of practice, the process becomes straightforward. Here’s a step-by-step guide to using the Lisle 16750:

- Preparation: Remove the necessary engine components to access the valve springs. Consult your vehicle’s service manual for specific instructions.

- Positioning: Position the Lisle 16750 over the valve spring retainer.

- Compression: Rotate the handle of the tool to compress the valve spring. Ensure the tool is securely positioned to prevent slippage.

- Retainer Removal: Once the spring is compressed, use appropriate tools to remove the valve keepers or retainers.

- Spring and Seal Removal: Carefully remove the compressed valve spring and any associated seals.

- Installation: Reverse the process to install new valve springs, seals, and retainers.

Tips for Effective Use

- Lubrication: Apply a small amount of lubricant to the contact points of the tool for smoother operation.

- Even Compression: Ensure even compression of the valve spring to prevent damage to the valve stem or retainers.

- Proper Alignment: Align the tool correctly with the valve spring retainer to avoid slippage and potential injury.

Benefits of Using the Lisle 16750 Valve Spring Compressor

The Lisle 16750 offers several advantages over other valve spring compressor tools:

- On-Engine Operation: Allows for valve spring service without removing the cylinder head.

- Ease of Use: Its simple design and operation make it user-friendly for both professionals and DIYers.

- Reduced Risk of Damage: The tool’s secure grip minimizes the risk of damaging the valve train components.

“The Lisle 16750 is a game-changer for valve spring service. Its on-engine operation saves me a significant amount of time and hassle.” – John Davis, Master Automotive Technician

Lisle 16750 vs. Other Valve Spring Compressors

While several valve spring compressors are available on the market, the Lisle 16750 stands out due to its unique features and benefits. Compared to traditional C-clamp style compressors, the Lisle 16750 offers improved stability and control, reducing the risk of slippage.

“I’ve used many valve spring compressors over the years, and the Lisle 16750 is by far the most efficient and user-friendly. I highly recommend it to anyone working on valve trains.” – Maria Rodriguez, Automotive Engineer

Conclusion

The Lisle 16750 car valve spring compressor tool is an indispensable tool for anyone performing valve service. Its efficiency, safety features, and versatility make it a valuable asset for both professional mechanics and DIY enthusiasts. By understanding its proper usage and benefits, you can significantly improve your workflow and achieve professional-grade results.

FAQ

- What types of engines is the Lisle 16750 compatible with?

- Can I use the Lisle 16750 on overhead cam engines?

- What safety precautions should I take when using this tool?

- How do I maintain the Lisle 16750?

- Where can I purchase the Lisle 16750?

- Are there any alternative tools I can use if I don’t have the Lisle 16750?

- Can the Lisle 16750 be used on diesel engines?

For assistance, contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 910 Cedar Lane, Chicago, IL 60605, USA. We have a 24/7 customer support team.

Leave a Reply