Press tools for cars are essential equipment in any automotive workshop, offering mechanics the power and precision needed for tasks ranging from simple bearing removal to complex chassis repairs. Understanding the various types, applications, and proper usage of these tools is crucial for both professional mechanics and DIY enthusiasts. This guide provides valuable insights into the world of automotive press tools.

A press tool, in its simplest form, utilizes mechanical or hydraulic force to apply pressure. This pressure can be used for a multitude of applications, including installing and removing bearings, bushings, gears, and other press-fit components. It’s also invaluable for bending, straightening, and shaping metal parts. Choosing the right press tool for your needs can significantly improve efficiency and safety in the workshop. We’ll discuss choosing the correct car inspection tool for specific tasks later on.

Different Types of Press Tools for Cars

Several types of press tools are available, each designed for specific tasks. Understanding these differences is key to selecting the appropriate tool.

Hydraulic Presses

Hydraulic presses are the workhorses of automotive workshops, utilizing hydraulic fluid to generate immense force. These presses are ideal for heavy-duty tasks like removing and installing large bearings, bushings, and ball joints. They offer superior power compared to manual presses, making them suitable for demanding applications.

Manual Presses

Manual presses, also known as arbor presses, offer a more portable and affordable option for smaller workshops or DIY enthusiasts. Operated by a hand lever or screw mechanism, these presses are perfect for lighter tasks such as installing smaller bearings and bushings. While not as powerful as hydraulic presses, they still offer considerable force for various applications.

Air/Pneumatic Presses

Powered by compressed air, air or pneumatic presses offer a good balance between power and portability. They are often faster than manual presses and suitable for repetitive tasks. These presses are commonly used in tire shops for mounting and demounting tires, showcasing their versatility. For those interested in other car maintenance tools, consider exploring options for a car tyre removal tool.

Hydraulic Press in Auto Shop

Hydraulic Press in Auto Shop

Specialized Press Tools

Beyond the common types mentioned above, specialized press tools cater to specific applications. These include:

- Ball Joint Press: Designed for removing and installing ball joints without damaging surrounding components.

- U-Joint Press: Specifically for servicing universal joints (U-joints) in drive shafts.

- Bearing Puller: Used to extract bearings from tight spaces without marring the shaft.

Choosing the Right Press Tool

Selecting the appropriate press tool depends on several factors, including the intended application, frequency of use, and budget. Consider the following:

- Capacity: The maximum force the press can exert. Choose a press with adequate capacity for the intended tasks.

- Working Space: The area available for working with the press.

- Portability: If portability is crucial, a manual or air/pneumatic press might be preferable.

- Price: Hydraulic presses generally cost more than manual or air presses.

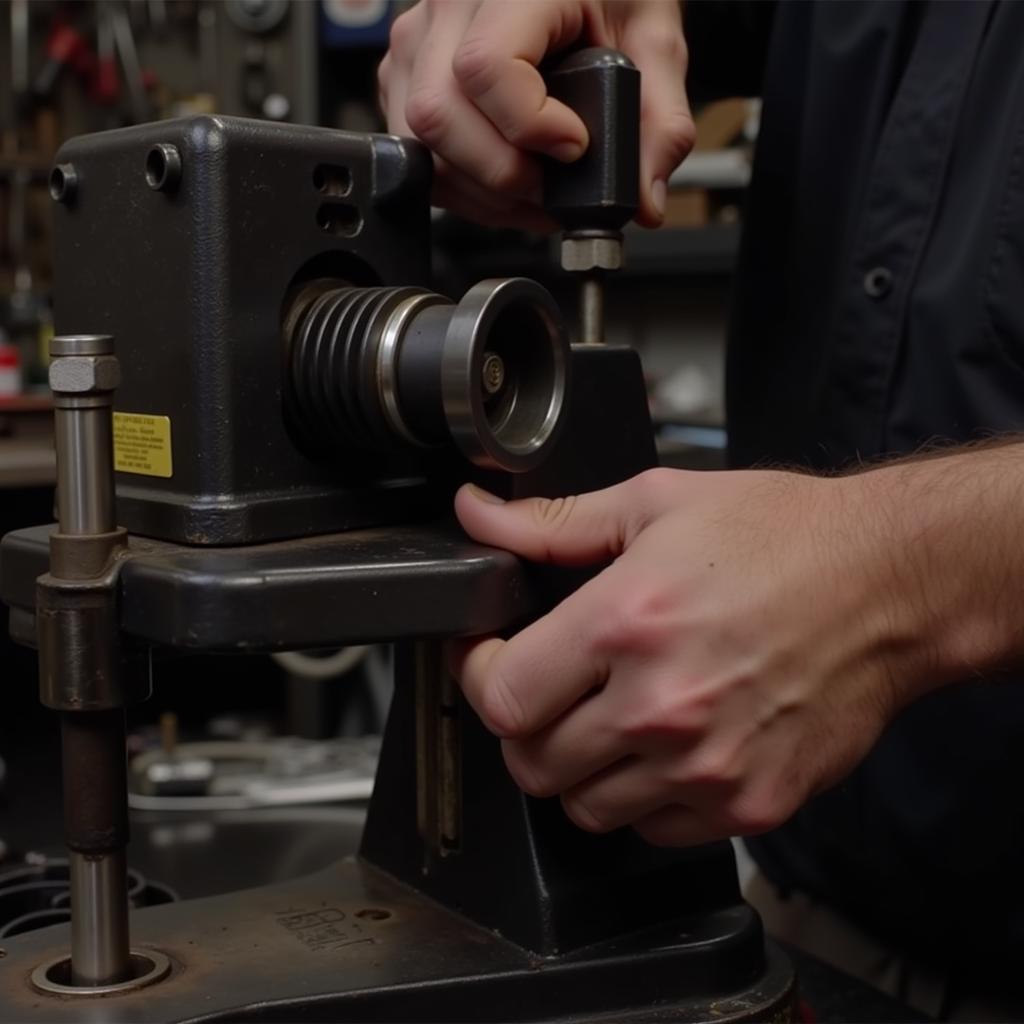

Mechanic Using a Manual Press

Mechanic Using a Manual Press

What is a press tool used for in a car?

A press tool is used in a car for a variety of tasks, primarily related to installing and removing press-fit components. This includes bearings, bushings, gears, and ball joints.

How do you use a press tool?

Using a press tool requires careful attention to safety and proper procedures. Always consult the manufacturer’s instructions for specific guidance. Generally, the process involves positioning the component correctly within the press, applying pressure gradually, and ensuring even force distribution. If you are interested in auto body work, you might find our article on the best tool for sanding car helpful.

Why is a press tool important?

Press tools provide controlled and precise force application, minimizing the risk of damage to components and surrounding parts. They also significantly improve efficiency compared to alternative methods.

When do I need a press tool for cars?

A press tool is essential when dealing with press-fit components that require a significant amount of force for installation or removal. Attempting these tasks without a press tool can lead to damaged parts and potential injury.

What are some safety precautions for using a press tool?

Always wear appropriate safety gear, including eye protection and gloves. Ensure the workpiece is secured properly and follow the manufacturer’s instructions carefully. Understanding how to use a rotary tool to buff a car can also contribute to your overall workshop safety knowledge.

Various Press Tool Attachments

Various Press Tool Attachments

Conclusion

Press tools for cars are indispensable for any automotive workshop, offering the power and precision needed for a wide range of tasks. From simple bearing replacements to complex chassis repairs, choosing the right press tool and using it correctly is crucial for efficiency, safety, and achieving professional results. Remember to always prioritize safety and consult the manufacturer’s instructions for specific guidance. For those interested in design aspects, we also offer resources on tools to draw cars.

FAQ

- What is the most common type of press tool for automotive use? Hydraulic presses are the most common due to their high force capacity.

- Can I use a manual press for heavy-duty tasks? While possible for some tasks, manual presses are generally better suited for lighter applications.

- Are air presses suitable for professional use? Yes, air presses are commonly used in professional settings, particularly for repetitive tasks.

- How do I maintain a hydraulic press? Regularly check the hydraulic fluid level and condition. Follow the manufacturer’s maintenance recommendations.

- What are some common applications for a ball joint press? Removing and installing ball joints in suspension systems.

- What is the benefit of using a bearing puller? It allows for the safe and efficient removal of bearings without damaging the surrounding components.

- Where can I find press tool attachments? Automotive tool suppliers and online retailers.

Common Scenarios and Questions

Scenario: A mechanic needs to replace a seized wheel bearing. Question: What type of press tool is best suited for this task? A hydraulic press would be the most efficient choice due to the force required to remove a seized bearing.

Scenario: A DIY enthusiast wants to replace bushings in their car’s control arms. Question: Is a manual press sufficient for this task? Yes, a manual press can be sufficient for replacing control arm bushings, especially if they are not excessively worn or seized.

Further Resources

Explore more articles related to automotive tools and repairs on DiagFixPro.

If you need further assistance, please contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 910 Cedar Lane, Chicago, IL 60605, USA. We have a 24/7 customer support team ready to help.

Leave a Reply