A special pully tension tool is essential for any car enthusiast or professional mechanic. It simplifies the process of replacing serpentine belts and ensures proper tension, preventing premature wear and potential engine damage. This guide will cover everything you need to know about these invaluable tools.

Understanding the Importance of a Special Pully Tension Tool

Replacing a serpentine belt seems simple enough, but without the right tools, it can quickly become a frustrating and potentially damaging ordeal. Improper tension can lead to belt slippage, reduced efficiency, and even complete belt failure. A special pully tension tool is designed to safely and effectively relieve tension on the belt tensioner, allowing you to easily remove and install the belt. This prevents damage to the tensioner pulley, the belt itself, and surrounding components.

Types of Special Pully Tension Tools

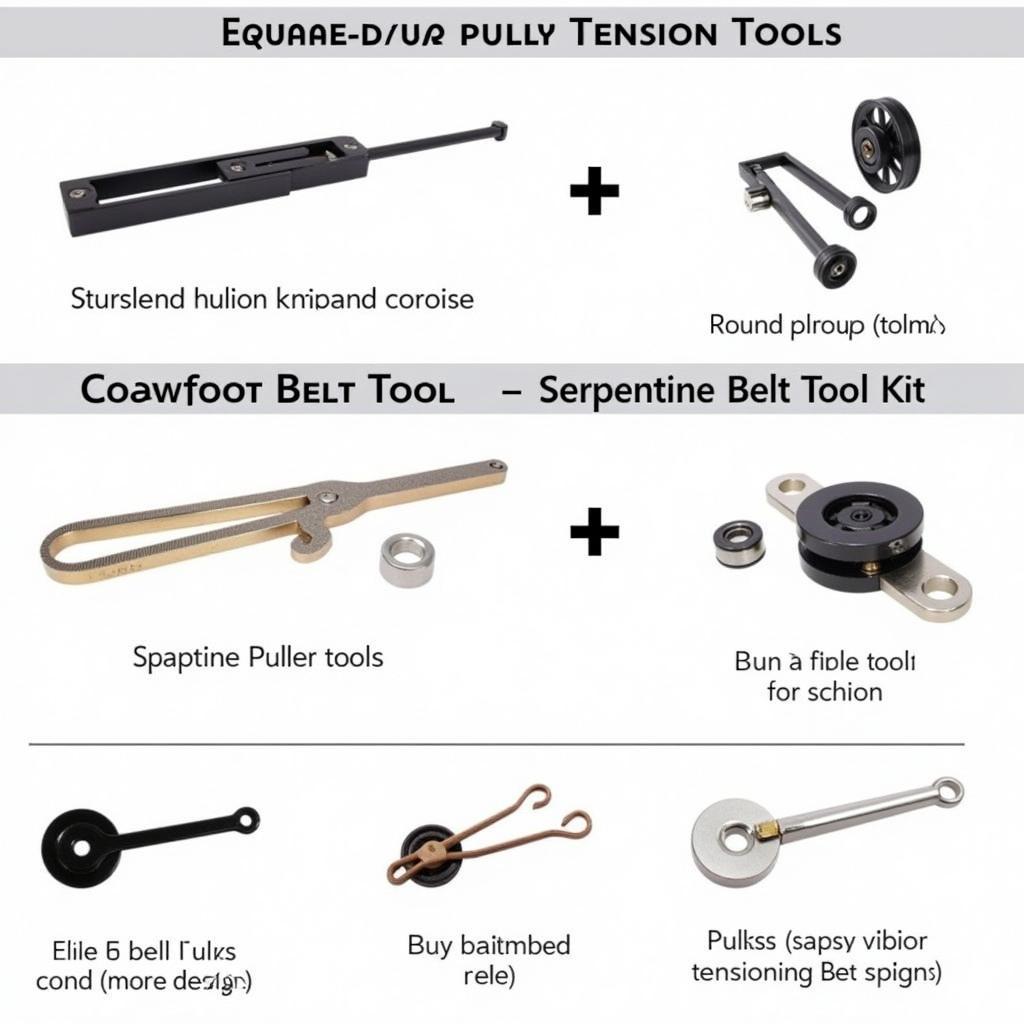

Several types of special pully tension tools cater to various engine configurations and belt routing systems. Understanding the different types can help you choose the correct tool for your specific needs.

-

Square Drive Tension Tools: These are common for many domestic and import vehicles and feature a square drive that engages with the tensioner pulley’s square receptacle.

-

Crowfoot Tension Tools: Ideal for tight spaces, crowfoot tension tools attach to a ratchet or breaker bar and provide leverage to rotate the tensioner pulley.

-

Serpentine Belt Tool Kits: These kits offer a comprehensive selection of tools to address a wide range of vehicle applications. They often include various adapters and extensions for different tensioner pulley designs.

Types of Special Pully Tension Tools

Types of Special Pully Tension Tools

How to Use a Special Pully Tension Tool

Using a special pully tension tool is generally straightforward, but it’s crucial to follow the correct procedure to avoid damage.

-

Identify the Belt Routing Diagram: Locate the belt routing diagram, typically found on a sticker under the hood or in the owner’s manual. This diagram shows the correct path of the serpentine belt.

-

Locate the Tensioner Pulley: Identify the tensioner pulley, which is usually a spring-loaded pulley with a square or other shaped receptacle.

-

Select the Correct Tool: Choose the appropriate special pully tension tool for your vehicle’s tensioner pulley.

-

Attach the Tool: Securely attach the tool to the tensioner pulley’s receptacle.

-

Apply Pressure: Apply smooth, steady pressure to the tool in the direction indicated on the tool or in the service manual. This will relieve the tension on the belt.

-

Remove and Install the Belt: While holding the tensioner in the released position, carefully remove the old belt and install the new one, following the routing diagram.

-

Release the Tension: Slowly release the tension on the tool, allowing the tensioner pulley to return to its normal position.

-

Double-Check the Routing: Verify that the new belt is correctly routed according to the diagram.

Choosing the Right Special Pully Tension Tool

Selecting the right special pully tension tool depends on several factors:

-

Vehicle Make and Model: Different vehicles use different tensioner pulley designs, so choosing a tool compatible with your specific car is essential.

-

Accessibility: Consider the space available around the tensioner pulley. A crowfoot tension tool might be necessary in tight spaces.

-

Budget: While individual tools are more affordable, a serpentine belt tool kit offers greater versatility for future repairs.

Benefits of Using the Correct Tool

Using the correct special pully tension tool offers several benefits:

-

Prevents Damage: Protects the tensioner pulley, belt, and surrounding components from damage.

-

Saves Time: Simplifies the belt replacement process, reducing repair time.

-

Ensures Proper Tension: Guarantees correct belt tension for optimal performance and longevity.

“Using the right tool is not just about convenience, it’s about preventing costly repairs down the road,” says John Smith, Senior Automotive Engineer at DiagFixPro.

Choosing the Right Special Pully Tension Tool

Choosing the Right Special Pully Tension Tool

Conclusion

A special pully tension tool is a must-have for any car owner or mechanic undertaking serpentine belt replacements. Choosing the right tool and using it correctly ensures proper belt tension, prevents damage, and ultimately saves you time and money. By understanding the different types of tools available and following the proper procedures, you can perform this essential maintenance task with confidence.

FAQs

-

Q: How often should I replace my serpentine belt?

- A: Consult your owner’s manual for the recommended replacement interval.

-

Q: What are the signs of a worn serpentine belt?

- A: Squealing noises, visible cracks, or fraying.

-

Q: Can I use a regular wrench instead of a special pully tension tool?

- A: While possible in some cases, it’s not recommended as it can damage the tensioner or surrounding components.

-

Q: Where can I find the belt routing diagram for my car?

- A: Typically under the hood or in your owner’s manual.

Need assistance? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 910 Cedar Lane, Chicago, IL 60605, USA. Our customer service team is available 24/7.

Leave a Reply