A tool and die maker career offers skilled individuals a chance to combine precision, creativity, and technical expertise. This guide delves into the world of tool and die making, exploring the required skills, education pathways, career progression, and future prospects. Discover how you can forge a successful career in this demanding yet rewarding field.

What Does a Tool and Die Maker Do?

Tool and die makers are highly skilled craftspeople who produce precision tools and dies used in manufacturing processes. They work with a variety of materials, including metal, plastic, and composites, to create tools used for shaping, cutting, and forming parts. These parts are then used in everything from cars and airplanes to medical devices and consumer electronics. Think of them as the architects of manufacturing, designing and building the very instruments that bring products to life. For those interested in a hands-on, technical career, tool and die making offers a unique blend of artistry and engineering. tool and die maker career path

Entering the Tool and Die Maker Career Path

How do you embark on a tool and die maker career? There are several pathways to becoming a qualified tool and die maker. A common route is through apprenticeships, which combine on-the-job training with classroom instruction. This approach allows aspiring professionals to learn directly from experienced mentors while developing practical skills. Alternatively, vocational schools and technical colleges offer programs specifically designed for tool and die making, providing a more structured learning environment. tools to make a car

Essential Skills for a Tool and Die Maker

A successful tool and die maker career requires a specific set of skills. Strong mathematical aptitude and problem-solving abilities are crucial for interpreting blueprints and designing complex tools. Manual dexterity and precision are essential for operating machinery and handling intricate parts. Additionally, computer skills are increasingly important as Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) technologies are becoming more prevalent in the industry.

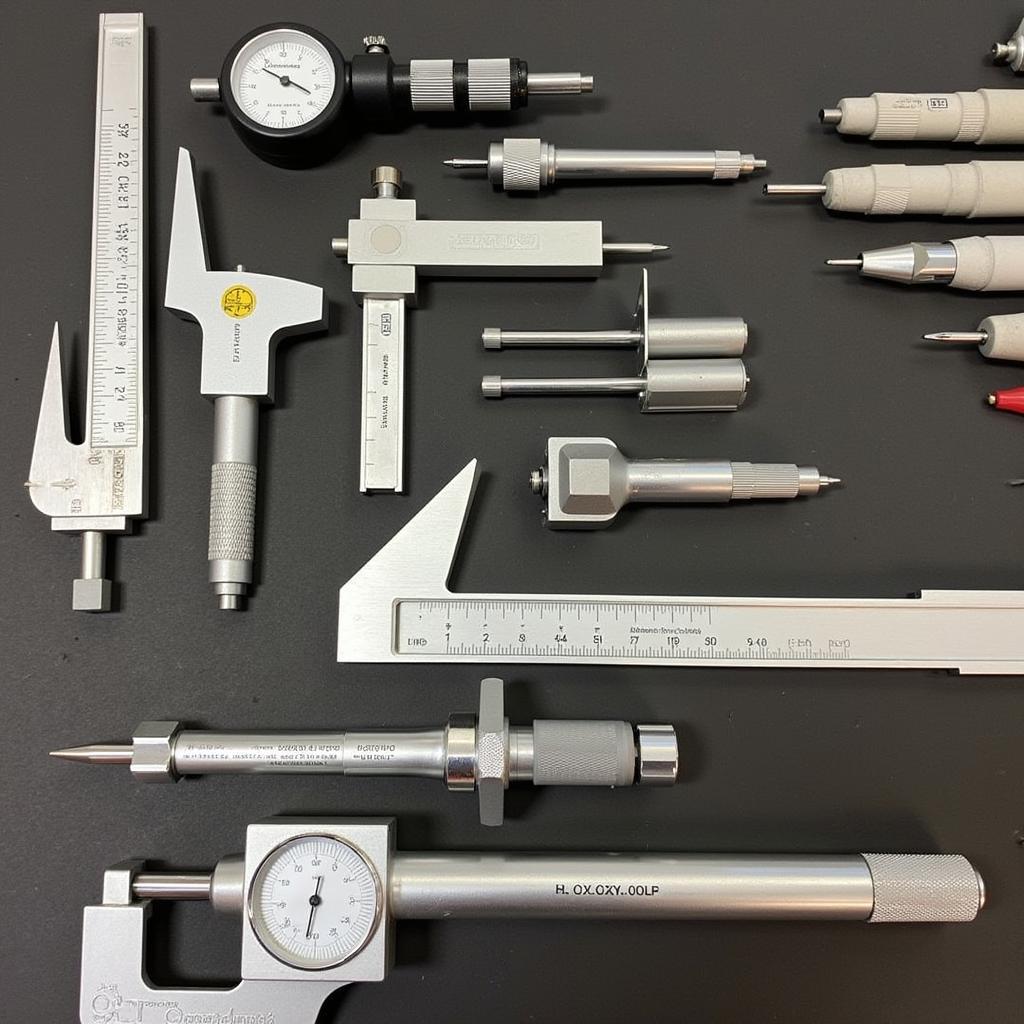

Precision measurement tools used in tool and die making, such as calipers and micrometers.

Precision measurement tools used in tool and die making, such as calipers and micrometers.

Tool and Die Maker Career Advancement

As tool and die makers gain experience and expertise, they can advance their careers in various directions. Some choose to specialize in a particular area, such as mold making or die casting. Others may move into supervisory or management roles, overseeing teams of tool and die makers. With the continuous advancements in technology, the field also offers opportunities for specializing in CAD/CAM programming and operation. tool engineer career

The Future of the Tool and Die Maker Career

The demand for skilled tool and die makers is expected to remain steady in the coming years. Although automation and advanced manufacturing techniques are transforming the industry, the need for skilled professionals to design, build, and maintain these sophisticated systems continues to grow. This ensures a promising future for individuals seeking a tool and die maker career.

“The tool and die industry is evolving rapidly, with increasing integration of automation and digital technologies. Adaptability and a willingness to learn new skills are essential for staying competitive in this dynamic field,” says John Smith, a seasoned Tool and Die Maker with over 20 years of experience.

Conclusion: Forging Your Path in the Tool and Die Maker Career

A tool and die maker career provides a fulfilling path for those who enjoy working with their hands and possess a keen eye for detail. This profession offers a blend of traditional craftsmanship and cutting-edge technology, promising a dynamic and rewarding career journey. survey tools used to assess physician career satisfaction how to care for craftsman tools

FAQ

- What is the average salary of a tool and die maker?

- What are the typical working conditions in this field?

- How long does it take to become a qualified tool and die maker?

- What are the key personality traits for success in this career?

- What are the major industry sectors that employ tool and die makers?

- What are some common challenges faced by tool and die makers?

- What are the continuing education opportunities for tool and die makers?

Common Situations and Questions

- How to choose the right apprenticeship program? Research various programs, considering factors like location, curriculum, and employer partnerships.

- What are the safety precautions in tool and die making? Safety glasses, gloves, and proper machine operation are crucial to prevent injuries.

- How can I stay updated with the latest industry trends? Attend industry conferences, workshops, and engage with online resources.

Further Exploration

Consider exploring related careers such as mold maker, tool designer, and CNC programmer.

Need further assistance? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected], or visit us at 910 Cedar Lane, Chicago, IL 60605, USA. Our 24/7 customer service team is ready to help.