Pressing wheel bearings while the car is still assembled is a tricky business, often requiring specialized tools. Using the right Tool To Press Wheel Bearings While On The Car can save you time, effort, and potential damage to surrounding components. This guide will delve into the specifics of these tools, their benefits, and how to use them effectively.

Understanding the Need for On-Car Bearing Presses

Why would you want to press wheel bearings without disassembling the entire hub assembly? Sometimes, it’s simply more efficient. Certain vehicles have complex suspension setups making traditional bearing replacement a lengthy process. On-car bearing presses offer a solution, allowing you to work directly on the vehicle, minimizing disassembly time. This method often requires less specialized equipment compared to traditional methods. Plus, it reduces the risk of damaging related components during disassembly and reassembly. You might be interested in our northern tool car dolly for further assistance with car maintenance.

Benefits of Using an On-Car Bearing Press

Using the right tool to press wheel bearings while on the car offers several advantages:

- Time Savings: Reduced disassembly and reassembly time translates into quicker repairs.

- Reduced Risk of Damage: By minimizing handling of delicate suspension components, you lessen the chances of accidental damage.

- Cost-Effectiveness: While the initial investment in an on-car press might seem significant, the long-term savings in labor and potential repairs can be substantial.

- Versatility: Many on-car presses accommodate a variety of bearing sizes and vehicle makes.

Choosing the Right Tool to Press Wheel Bearings While on the Car

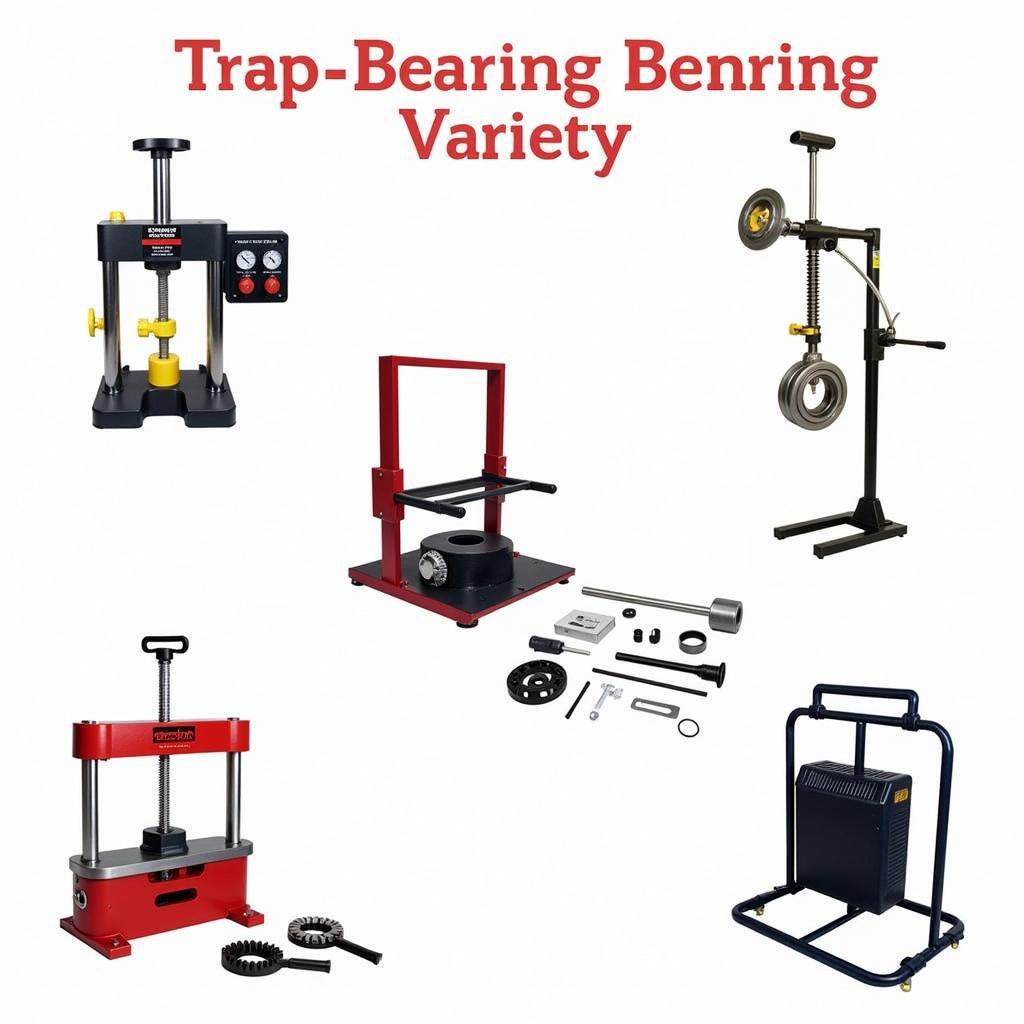

Various on-car bearing press tools available

Various on-car bearing press tools available

Several factors influence the choice of an on-car bearing press:

- Vehicle Application: Certain presses are specifically designed for specific makes and models.

- Bearing Size: Ensure the press can accommodate the diameter of the bearings you typically work with.

- Power Source: Hydraulic and mechanical presses offer different levels of force and control. Hydraulic presses generally offer more controlled and powerful pressing.

- Budget: Prices vary greatly depending on features and brand.

How to Use a Tool to Press Wheel Bearings While on the Car

The process generally involves these steps (always refer to the manufacturer’s instructions for your specific tool):

- Preparation: Clean the bearing and surrounding area. Ensure you have the correct adapters for your specific vehicle.

- Positioning: Carefully position the press against the bearing, ensuring it’s aligned correctly.

- Pressing: Slowly and steadily apply pressure to press the bearing into place. Avoid jerky movements or excessive force.

- Verification: Once pressed, verify the bearing is seated correctly and rotates smoothly.

Tips for Successful Bearing Pressing

- Lubrication: Properly lubricate the bearing and the press components to minimize friction and ensure smooth operation.

- Even Pressure: Apply pressure evenly to avoid damaging the bearing or surrounding components.

- Patience: Rushing the process can lead to mistakes. Take your time and work methodically. Remember, having the correct tools, like a 86 lincoln town car hubcap removal tool, for other parts of the car can make your overall maintenance experience much smoother.

“Proper lubrication and even pressure application are essential for successful bearing replacement,” says John Miller, a seasoned automotive technician with over 25 years of experience. He further emphasizes the importance of choosing the right tool: “Investing in a quality on-car bearing press can save you significant time and hassle in the long run.”

Conclusion

Choosing the right tool to press wheel bearings while on the car can drastically improve your efficiency and the quality of your work. By understanding the different types of presses available and following proper procedures, you can achieve professional results, saving time and minimizing the risk of damage. Investing in the correct tool, even something seemingly simple like a northern tool car trailer wheelbearing kit, makes all the difference. Proper bearing maintenance contributes significantly to the overall safety and performance of the vehicle.

FAQ

- Are on-car bearing presses universal? No, different presses are designed for specific vehicles and bearing sizes.

- What are the advantages of using an on-car press compared to traditional methods? Time savings, reduced risk of damage, and cost-effectiveness are some key advantages.

- Is it essential to lubricate the bearing before pressing? Yes, lubrication is crucial for smooth operation and preventing damage.

- What should I do if the bearing doesn’t press in smoothly? Stop immediately and re-evaluate your setup. Ensure proper alignment and lubrication.

- Where can I find a reliable on-car bearing press? Reputable automotive tool suppliers carry a variety of options.

- Can I use an on-car press for all types of bearings? No, certain presses are designed for specific bearing types. Check compatibility before use.

- What’s the average lifespan of a wheel bearing? Wheel bearing lifespan varies depending on driving conditions and vehicle type but generally lasts between 80,000 to 100,000 miles.

Common Scenarios and Questions

Scenario: You’re working on a car with limited access to the wheel hub assembly. Question: Is an on-car bearing press a viable solution? Yes, on-car presses are ideal for situations with limited access.

Scenario: You’re working on a high-volume repair shop. Question: How can an on-car bearing press improve efficiency? By reducing repair time, an on-car press allows you to handle more jobs efficiently.

Further Resources

For more information on car maintenance and tools, consider checking out our articles on maintenance and care of simple farm tools and car knuckle hub-shark press tools.

Need help? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected], or visit us at 910 Cedar Lane, Chicago, IL 60605, USA. We offer 24/7 customer support.

Leave a Reply