Car crushing is a vital part of the automotive lifecycle, ensuring responsible recycling and resource management. Whether you’re a scrapyard operator, a demolition derby enthusiast, or simply curious about the process, understanding the tools for car crushing is essential. This article will explore the various equipment and techniques used in this industry.

Understanding the Need for Car Crushing Tools

Before diving into the specifics of the tools, it’s important to understand why car crushing is necessary. Vehicles reaching the end of their lifespan often contain hazardous materials like fluids and batteries that need proper disposal. Crushing reduces the vehicle’s volume, making transportation and recycling more efficient. It also allows for easier separation of various materials like steel and aluminum. For businesses like salvage yards, choosing the right car crushing tools is critical for efficiency and profitability. Perhaps you need a car oil filter removal tool strap wrench to initially drain the fluids before the crushing process.

Key Tools Used in Car Crushing

The Mighty Car Crusher

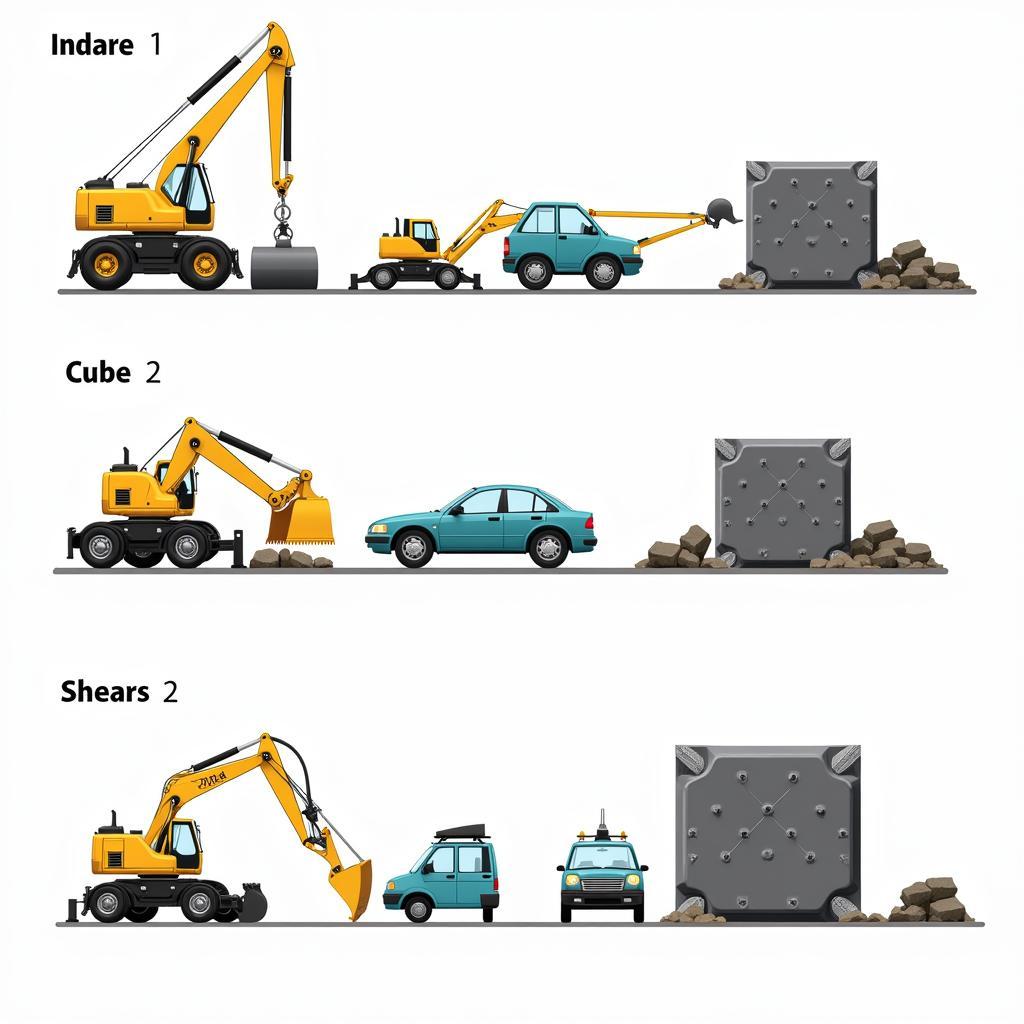

The centerpiece of any car crushing operation is, of course, the car crusher itself. These powerful machines come in various sizes and configurations, from smaller mobile crushers to massive stationary installations. The most common type is the hydraulic crusher, which utilizes immense hydraulic pressure to compact a vehicle into a manageable cube. These crushers often feature powerful jaws or plates designed to withstand the tremendous forces involved.

Choosing the right crusher depends on the volume of vehicles being processed and the available space. Some crushers are designed for specific materials, making them more effective for targeted recycling efforts. The tool to get hoses off car might be useful when dismantling parts before crushing.

Supporting Equipment for Efficient Crushing

The car crusher itself is only part of the equation. Several supporting tools are crucial for a smooth and efficient crushing operation. These include:

- Cranes and Grapples: Used to lift and position vehicles onto the crusher platform.

- Shears and Cutters: Employed for dismantling parts of the vehicle prior to crushing, such as removing the roof or cutting off large sections.

- Conveyors: Transport crushed material for further processing and separation.

- Balers: Compact and bundle crushed materials for easier storage and shipping. Sometimes, tools similar to those used for car brake pipe tools can be helpful in the dismantling process.

“Efficiency is key in car crushing,” says John Miller, a veteran scrapyard operator with 20 years of experience. “Investing in the right supporting equipment can significantly reduce processing time and improve overall productivity.”

Safety Considerations and Best Practices

Car crushing involves inherent risks, and safety should always be a top priority. Operators must adhere to strict safety protocols and wear appropriate personal protective equipment (PPE). Regular maintenance and inspections of the equipment are vital to prevent accidents and ensure the longevity of the tools.

“Safety is paramount,” emphasizes Sarah Johnson, a leading expert in industrial safety. “Proper training and adherence to safety guidelines are essential for protecting workers and ensuring a safe working environment.” Choosing the correct tools for the job, even seemingly simple ones like a hardline tools car heater defroster, can have unexpected safety benefits.

Future Trends in Car Crushing Technology

The car crushing industry is constantly evolving, with new technologies and techniques emerging to improve efficiency and sustainability. Automated systems, robotic arms, and advanced material separation methods are becoming increasingly prevalent. These advancements not only streamline the process but also contribute to better resource recovery and environmental protection. Understanding the proper selection use and care of bar tools and equipment can be unexpectedly relevant to maintaining car crushing tools as well.

Conclusion

Choosing the right tools for car crushing is crucial for efficient and safe operations. From the main crusher to the supporting equipment, understanding the function and application of each tool is essential for maximizing productivity and minimizing risks. As the industry continues to advance, embracing new technologies will be key to achieving greater sustainability and resource optimization in car crushing. tools for car crushing are an investment in responsible recycling.

FAQ

- What is the most common type of car crusher?

- What safety precautions are necessary for car crushing?

- What are the future trends in car crushing technology?

- How does car crushing contribute to environmental protection?

- What are the different types of supporting equipment used in car crushing?

- How do I choose the right size car crusher for my needs?

- What are the benefits of using a hydraulic car crusher?

Need Assistance? Contact us via WhatsApp: +1(641)206-8880, Email: cardiagtechworkshop@gmail.com, or visit us at 910 Cedar Lane, Chicago, IL 60605, USA. We offer 24/7 customer support.