A wedge tool is a simple yet powerful device used for various applications, including moving train cars. Understanding its function and safe operation is crucial for anyone working in the rail industry. This article provides a comprehensive overview of wedge tools, their types, uses, and safety considerations. tools to get into car

Understanding the Wedge Tool for Train Cars

Wedge tools for train cars are specifically designed to create a slight movement in stationary rail cars, allowing for coupling, uncoupling, or minor adjustments in positioning. They function by applying a leveraging force against the wheel of the train car. The wedge’s sloped surface amplifies the applied force, resulting in the car’s movement.

Types of Wedge Tools

There are various types of wedge tools available, each designed for specific applications and train car wheel sizes. Some common types include:

- Standard Rail Car Wedge: A common type used for most rail car applications.

- Heavy-Duty Rail Car Wedge: Designed for larger, heavier train cars, providing increased leverage.

- Non-Sparking Rail Car Wedge: Made from non-ferrous materials, minimizing the risk of sparks in potentially hazardous environments.

Different wedges are suitable for different tasks. Choosing the correct wedge is crucial for safe and efficient operation.

How to Use a Wedge Tool Safely

Using a wedge tool requires careful attention to safety procedures to prevent accidents and injuries. The following steps outline the proper use of a wedge tool:

- Assess the Situation: Before using a wedge tool, inspect the area around the train car, ensuring a clear and level work surface.

- Choose the Right Wedge: Select the appropriate wedge based on the train car’s size and weight.

- Position the Wedge: Carefully place the wedge against the wheel of the train car, ensuring it’s firmly seated.

- Apply Force: Gradually apply force to the wedge, observing the car’s movement.

- Monitor Movement: Continuously monitor the train car’s movement, ensuring it’s moving in the desired direction.

- Remove the Wedge: Once the desired movement is achieved, carefully remove the wedge.

Importance of Proper Training

Proper training is essential for anyone using wedge tools. Training should cover proper usage, safety procedures, and potential hazards. This ensures the operator’s safety and prevents damage to the train car.

Common Mistakes to Avoid

- Using the wrong wedge: This can lead to ineffective movement or damage to the wedge and the train car’s wheel.

- Applying excessive force: This can result in the wedge breaking or the train car moving uncontrollably.

- Not inspecting the work area: Debris or uneven surfaces can cause the wedge to slip, leading to accidents.

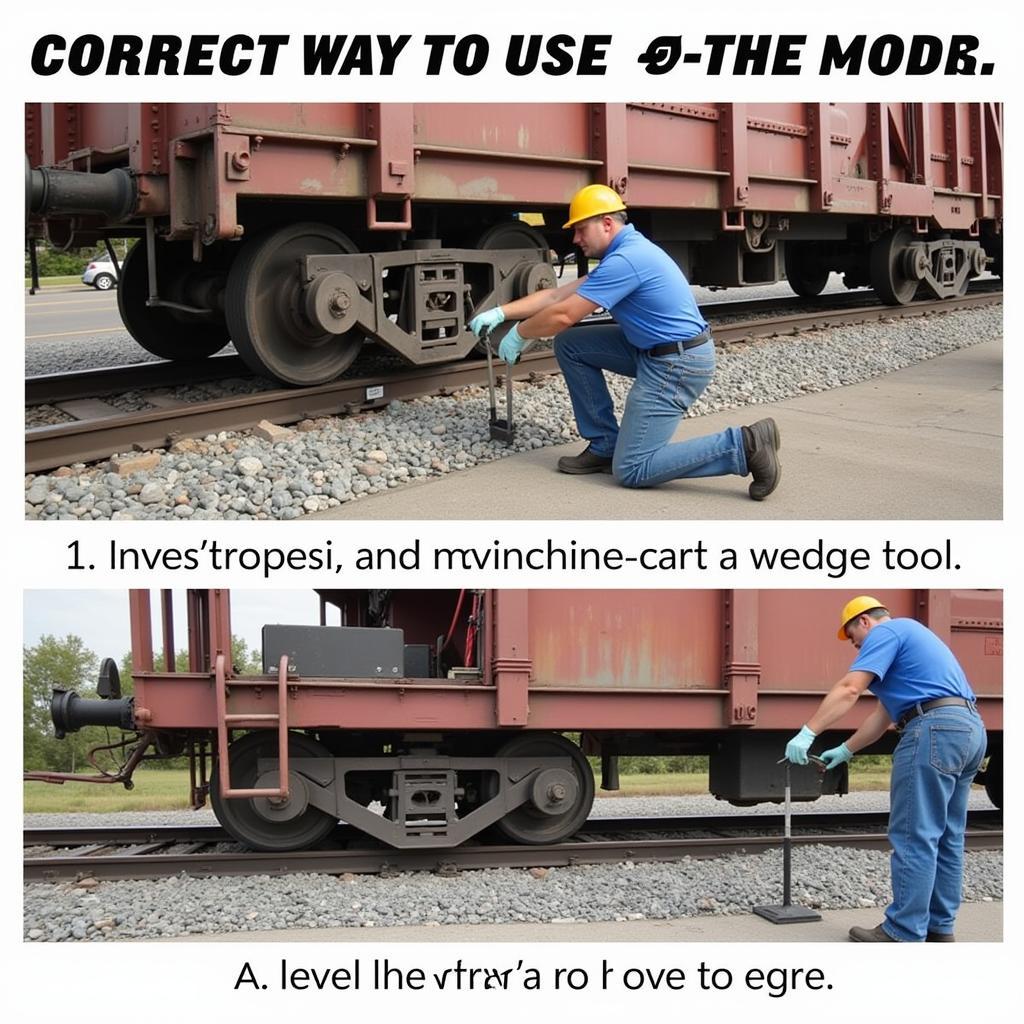

Correctly Using a Wedge Tool on a Train Car Wheel

Correctly Using a Wedge Tool on a Train Car Wheel

Maintenance and Inspection of Wedge Tools

Regular inspection and maintenance of wedge tools are critical for ensuring their longevity and safe operation. Checks should include looking for cracks, wear, and any signs of damage. Damaged wedges should be replaced immediately.

“Regular inspections and maintenance are essential for preventing accidents and ensuring the effectiveness of your wedge tools,” advises John Davis, a seasoned railway technician with over 20 years of experience. He further emphasizes, “A damaged wedge can compromise safety and lead to costly repairs.”

Choosing the Right Wedge Tool

Selecting the appropriate wedge tool is paramount for both safety and effectiveness. Consider the following factors when making your choice:

- Train car weight: Heavier cars require heavier-duty wedges.

- Wheel size: The wedge should be compatible with the train car wheel size.

- Working environment: Choose non-sparking wedges for hazardous environments.

- Material quality: Opt for durable, high-quality materials for longevity and reliability.

Conclusion

Wedge tools are essential tools for moving train cars, but their safe and efficient operation requires proper training, correct usage, and regular maintenance. By understanding the different types of wedges, following safety procedures, and choosing the right tool for the job, you can ensure the safe and effective movement of train cars. Using a Wedge Tool To Move Train Car is a crucial aspect of rail operations. Remember to prioritize safety and follow the guidelines outlined in this article.

“Investing in high-quality wedge tools and proper training is a worthwhile investment for any rail operation,” adds Maria Sanchez, a leading consultant in railway safety and operations. “It’s about prioritizing safety and ensuring the smooth running of operations.”

FAQ

- What is a wedge tool used for in the rail industry?

- What are the different types of wedge tools available?

- How do you use a wedge tool safely?

- What are the common mistakes to avoid when using a wedge tool?

- Why is regular inspection and maintenance of wedge tools important?

- How do I choose the right wedge tool for my application?

- What are the safety considerations when using a wedge tool?

Common Scenarios for Wedge Tool Use

- Coupling and uncoupling train cars

- Making minor adjustments to train car positioning

- Moving train cars short distances within a rail yard

Related Topics

- Rail car safety procedures

- Train car maintenance

- Rail yard operations

If you need further assistance, please contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit our office at 910 Cedar Lane, Chicago, IL 60605, USA. Our customer service team is available 24/7.

Leave a Reply